See our selection of Fermentors and Bioreactors

Click here to discover our products

Laval Lab offers the Solaris line of Fermenters and Bioreactors to meet customers’ needs, from laboratory bench top fermenters to pilot plant and production fermenters.

Whether you need a standard or customized solution in the field of biotechnology, we are the best partner to find the solution that suits your specific needs.

High quality manufacturing is your guarantee that the final product will meet all sophisticated standards.

We serve the following industries: Pharmaceutical, Cosmetics, Milk and Dairy processes, Petrochemicals, General process plants, Nutraceutical, Food Biotechnologies, Chemicals, Environmental, and Bioplastic.

Fermentor and Bioreactor Selection Guide

Bench-Top Mini Bioereactors Fermenters (IO series – 200 to 1000mL)

Laboratory Autoclave Bench-top Fermenters (Jupiter series ‘ 2L to 10L)

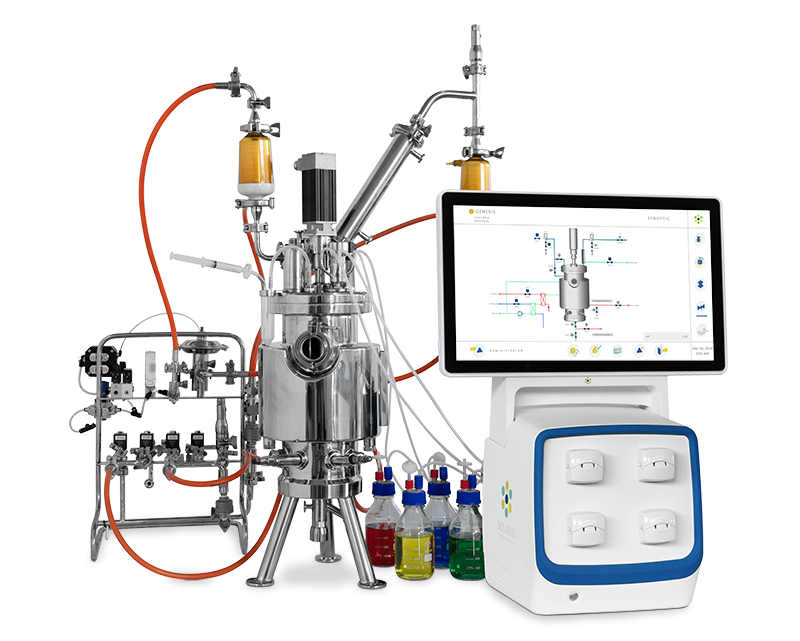

Sterilizable In-Place R&D Fermenter (Genesis series – 7.5 to 20L)

Photo Bioreactor (Elara 4L)

Laboratory SIP Fermenter (M series ‘ 30L to 200L)

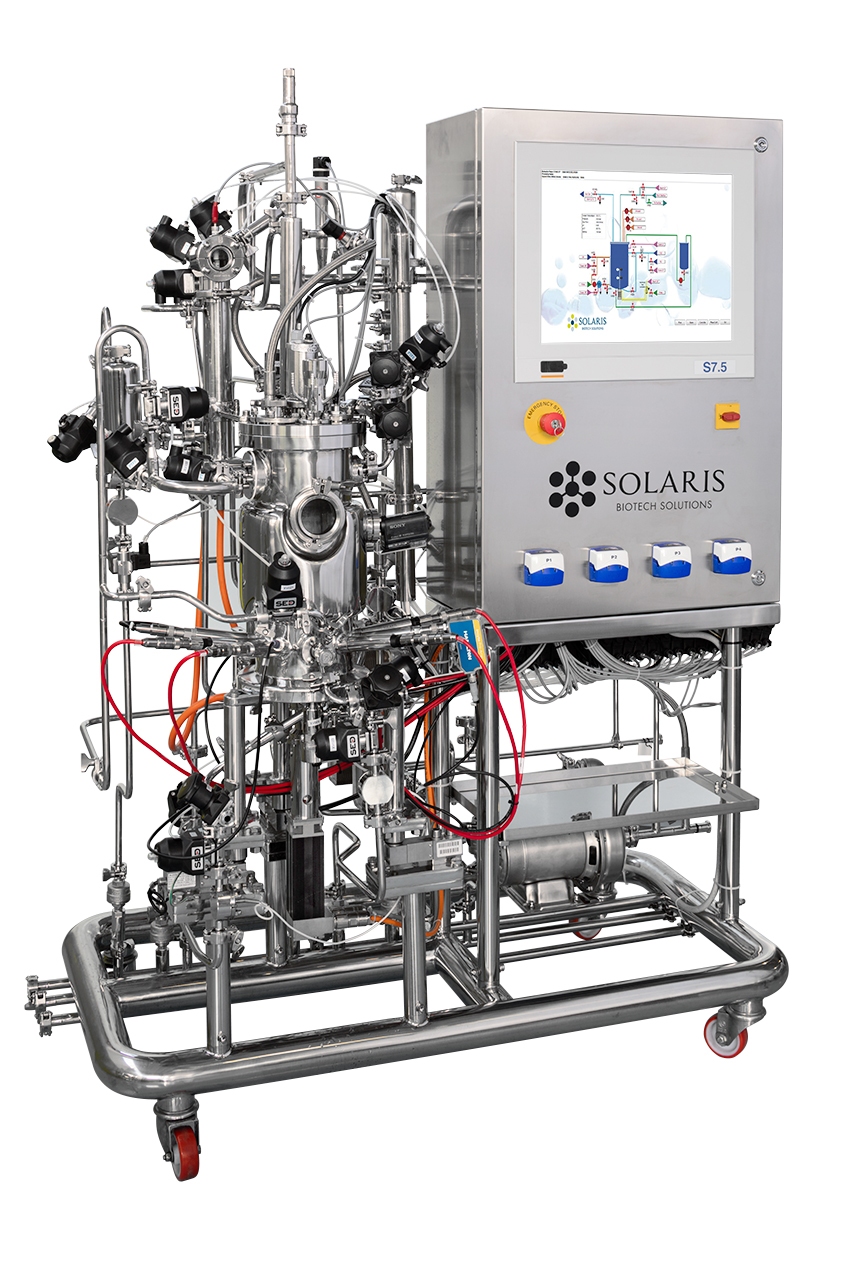

Pilot Scale Fermenter (S series, SIP ‘ 5L to 200L)

Industrial Scale Bioreactors (I series ‘ 300L to 30,000L)

Fermenter / Bioreactor – Process Control & Accessories

Gas Analyzers, Clean In Place / Steam In Place systems, Reactors, Flow filtration technologies (microfiltration, reverse osmosis).

Smart Control for Bench Top to Pilot and Production plants

- The control software is compatible with main operating platforms such as

Windows, MC, Linux; - The user interface consists of a monitor equipped with touch-screen, substituting the keyboard in all its functions;

- The monitor is usually placed in the high part of the control module, but it

can also be positioned in a remote position; - Acquisition of data in real time and conversion of the signals from sensors applied to the process into values expressed in the specific units of measure of each variable;

- Continuous graphic representation of the values, free choice of the variables represented and of the related scales;

- Control of choosing the control method (Maintenance, Program cascade, Off) and the values of the control parameters;

- Attribution to the variables of maximum and minimum values to act as alarm thresholds;

- Automatic sterilization of the fermenter with a wide range of choice of phase

temperature and durations; - Connection through Ethernet with other bioreactors, allied equipment and supervisory computer.

Downstream equipment

Best filtration membranes available on the market, in terms of materials, geometric configuration and operative parameters, for:

- Concentration with the best efficiency

- Avoiding problem of gel layer

- Increasing the efficiency in Diafiltration

Different forms of filtration

| Method | Pore size | Retained |

| Microfiltration | 100nm to 10 m | Cells, cell debris |

| Ultrafiltration | 10 to 100nm | Fine particles, viruses, large proteins |

| Nanofiltration | 1 to 10 nm | Proteins purification, virus clearance |

| Reverse osmosis | 0.1 to 1 nm | Water purification |