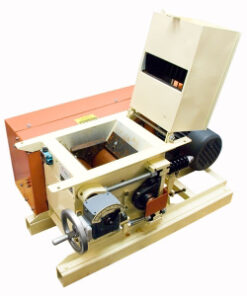

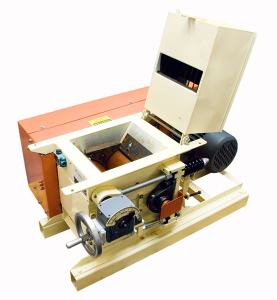

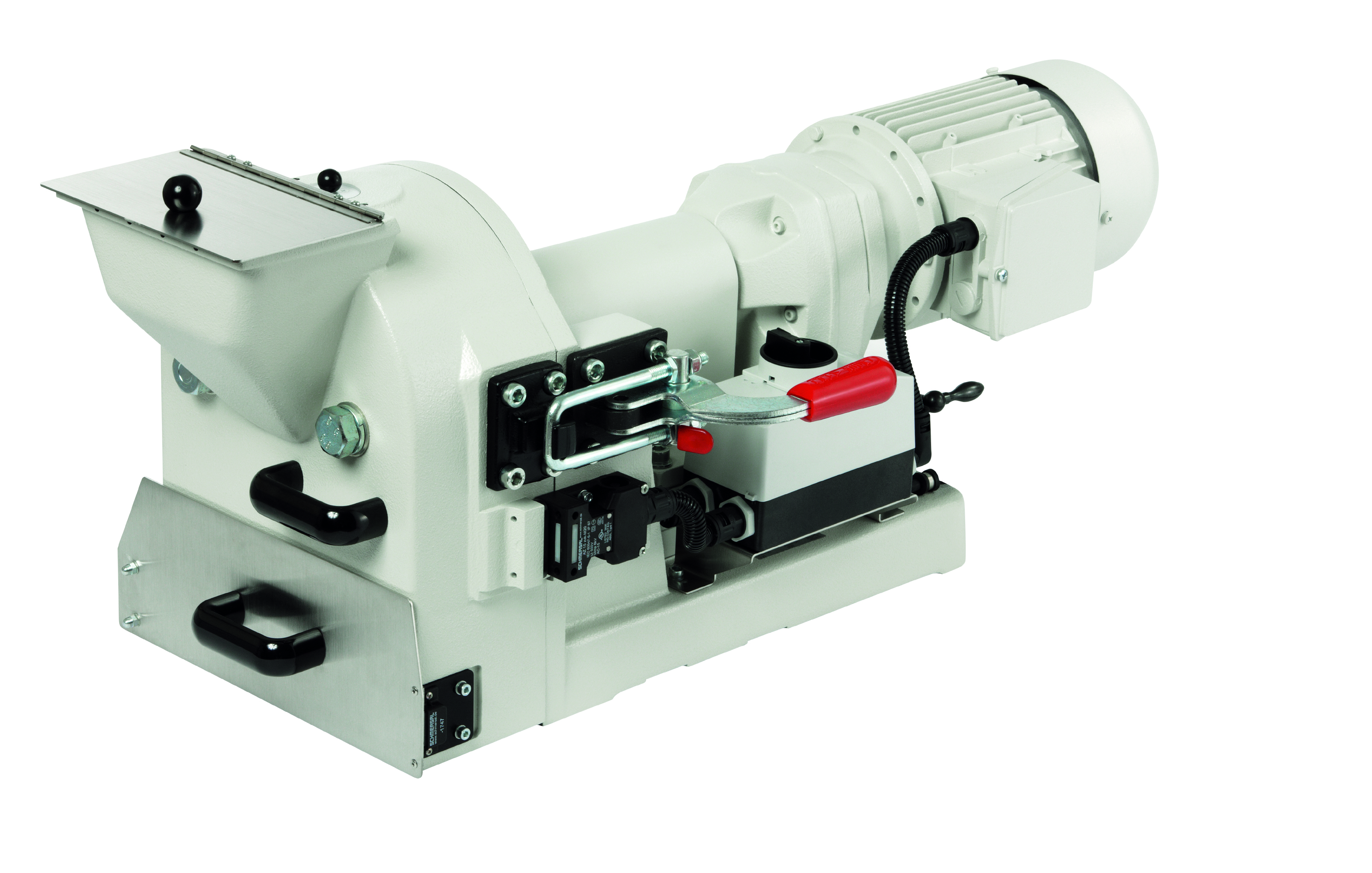

Universal Cutting Mill Pulverisette 19

The Universal Cutting Mill Pulverisette 19 is dedicated to grinding dry, soft to medium-hard, samples as well as fibrous materials and plastics.

The Universal Cutting Mill, Pulverisette 19, is suitable for grinding soft to medium-hard dry materials. With a feed size of up to 70 x 80 mm (depending on the material) and a throughput rate of up to 60 l/h, the universal cutting mill sets high standards.

The mill can be used, for example, to grind the following materials: rubber, leather, paper, cardboard, tissues, plastics, wood, non-metallic waste, coal, animal feeds, maize, grain, confectionery, malt, farinaceous products, spices, dried meat, bones, tablets, leaves, fibres, peat, roots, tobacco, cork, straw or film, LCD’s and keypads of mobile phones, circuit boards (populated and unpopulated), electronic chips.

Furthermore, the universal cutting mill can also be used in the pharmaceutical or animal feed industries, in dental, medicinal and metallurgical technology as well as in veterinary institutes.

Sample exhauster with cyclone separator

This type of collection is the most convenient because the ground material is transferred directly to a glass bottle, from which it can be easily removed, transported or stored. The strong air current cools and transports the ground material so that even samples which would normally be difficult to grind can be processed. Clogging of the sieve meshes is virtually negligible.

| Maximum feed size: | 70×80 mm (2-3/4×3’’) |

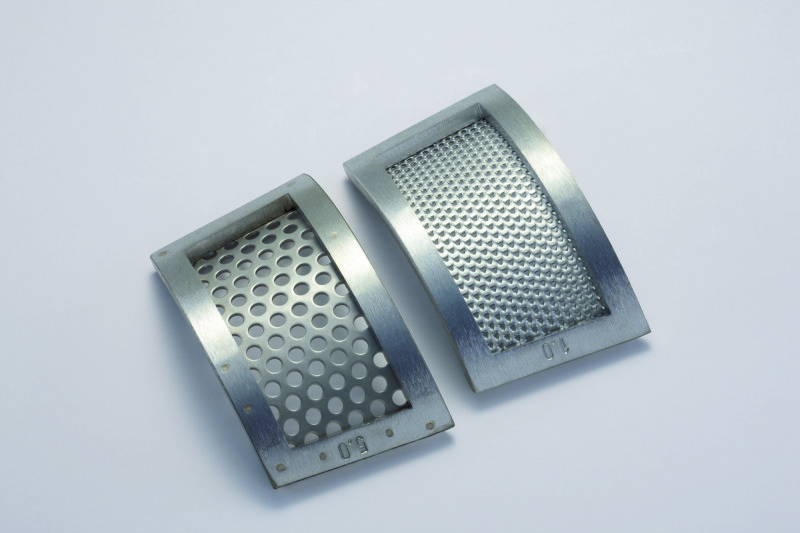

| Final fineness: | 0.2 to 6 mm (70 mesh to ¼’’), depending on sieve insert |

| Maximum capacity: | 60 L/h |

| Grinding materials: | Tempered stainless steel, tungsten carbide, chromium-free steel |

| Dimensions (WxDxH): | Table mounted or on stand 45x55x63cm (18x22x25’’) |

| Weight: | 125 lb. (56 kg) |

- Certified safety (CE mark) – optional CSA approval for Canada

- 2-year warranty

A rotor fitted with knives grind the sample in combination with three fixed knives. The material remains in the grinding chamber until the desired final fineness is reached, and then discharged through the mesh sieve insert into the collecting vessel. An optional exhaust system with cyclone separation is recommended. This type of collection is very efficient since the ground material is transferred directly to a glass bottle. The strong air current cools and transports the ground material so that even samples which would normally be difficult to grind, can be processed. Clogging of the sieve meshes is virtually negligible. At the same time, the cleaning is minimal.

- Fast, reproducible grinding, variable speed (50-700 rpm or 300-3000 rpm)

- Different rotors for adapting the cutting performance to the sample

- Easy-to-clean grinding chamber

- German quality

Related products

Crushers, Pulverizers, Grinders

Crushers, Pulverizers, Grinders

Marcy® Double Roll Crushers

$1The Marcy Double Roll Crusher meets your requirements for intermediate crushing of friable rock or rock-like materials

Crushers, Pulverizers, Grinders

Laboratory Jaw Crusher Pulverisette 1

$0This Laboratory Jaw Crusher is designed for fast and effective pre-crushing of very hard, hard, medium-hard, and brittle materials, even ferrous alloys.

Crushers, Pulverizers, Grinders

Mortar Grinder Pulverisette 2

$0The Automatic Mortar Grinder Pulverisette 2 is ideal for universal grinding of medium-hard-brittle to soft-brittle materials (dry or in suspension) to analytical fineness, as well as for formulation and homogenisation of pastes and creams at laboratory scale.

Crushers, Pulverizers, Grinders

Knife Mill Blender Pulverisette 11

$1The Knife Mill Homogenizer Pulverisette 11 is the ideal Laboratory Mixer for fast size reduction and homogenization of Food samples

Crushers, Pulverizers, Grinders

Planetary Mill Pulverisette 4 for mechanical alloying and mechanical activation

Planetary Mill Pulverisette 4 for mechanical alloying and mechanical activation

$1The Vario Planetary Mill Pulverisette 4 is ideal for mechanical activation and alloying. It offers the freedom to program all grinding parameters through PC software to achieve the desired effect on the sample.

Crushers, Pulverizers, Grinders

Laboratory Disc Pulverizer Pulverisette 13

$0The Laboratory Disc Pulverizer Pulverisette 13 is designed for batch or continuous fine grinding of hard-brittle to medium-hard solids.

Crushers, Pulverizers, Grinders

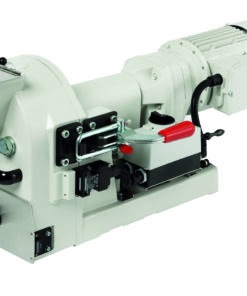

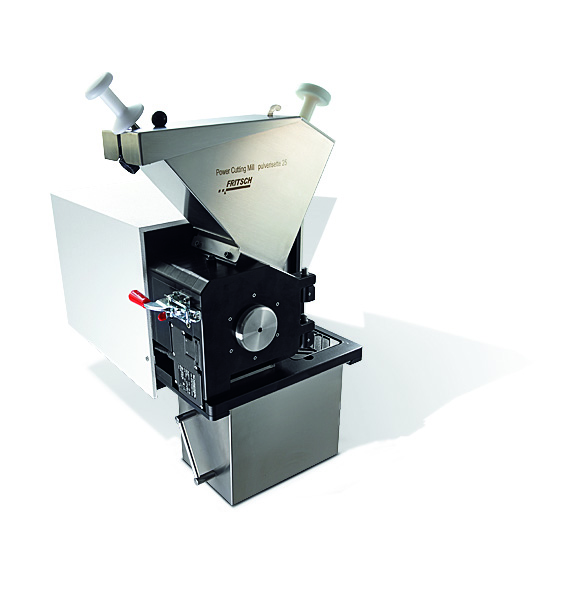

Power Cutting Mill Pulverisette 19 LARGE

$1The Pulverisette 19 Large is a powerful cutting mill for the coarse grinding of dry, soft to medium-hard or fibrous materials and plastics.