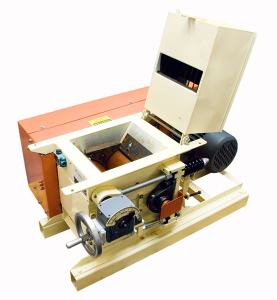

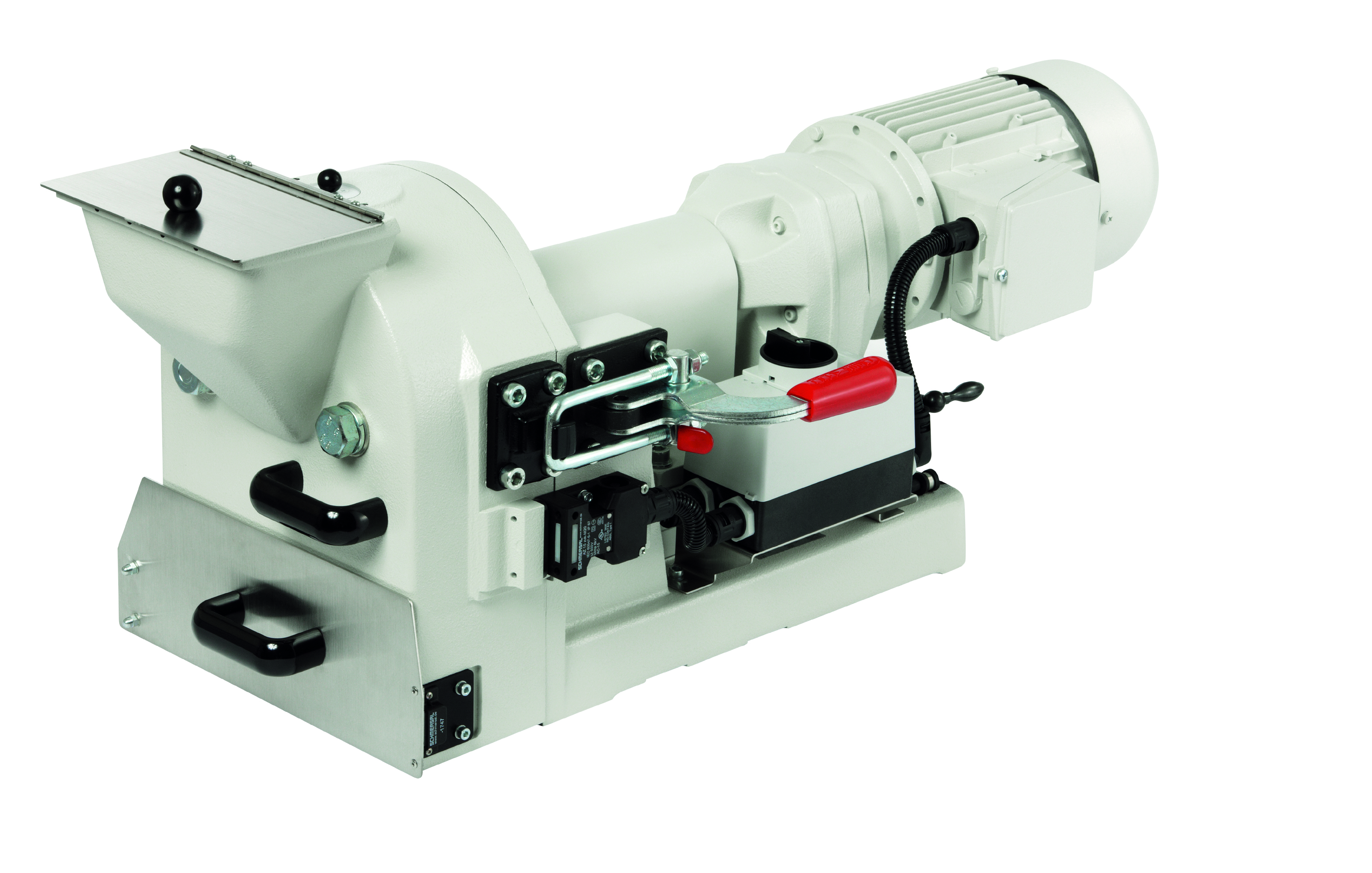

Marcy® Double Roll Crushers

The Marcy Double Roll Crusher meets your requirements for intermediate crushing of friable rock or rock-like materials

Double Roll Crushers are useful for intermediate size reduction of hard to medium hard materials, such as rock or ore, after processing with a jaw crusher, for final reduction with a pulverizer. They also bridge the gap between laboratory and continuous production or pilot plant crushing capacities. Especially recommended for assay offices, metallurgical, soil and other commercial or industrial laboratories.

Application: mining industry, high capacity intermediate crushing

| Model | 6000 6.5×6-inch (16.5×15 cm) | 8000 9×12-inch (23×30.5 cm) |

| Maximum feed size | 12.5 mm (1/2’’) | 12.5 mm (1/2’’) |

| Final fineness | 2 mm (10 mesh) | 2 mm (10 mesh) |

| Maximum capacity | 1360 kg/h (3000 lb./h) | 3600 kg/h (8000 lb./h) |

| Grinding materials | 304 SS with Ni-Hard facings | 304 SS with Ni-Hard facings |

| Dimensions (WxDxH) | 120x90x150 cm (48x36x58’’) w/base | 120x160x120 cm (48x64x46’’) no base |

| Weight | 360 kg (800 lb.) | 600 kg (1320 lb.) |

The particles are drawn into the gap between the rolls by their rotating motion and a friction angle formed between the rolls and the particles. The two rolls force the particles between their rotating surface into the ever smaller gap area, and it fractures from the compressive forces presented by the rotating rolls.

– High capacity intermediate crushing – Heavy duty equipment with minimal maintenance. – Final fineness easily set by setting gap between rolls

Related products

Crushers, Pulverizers, Grinders

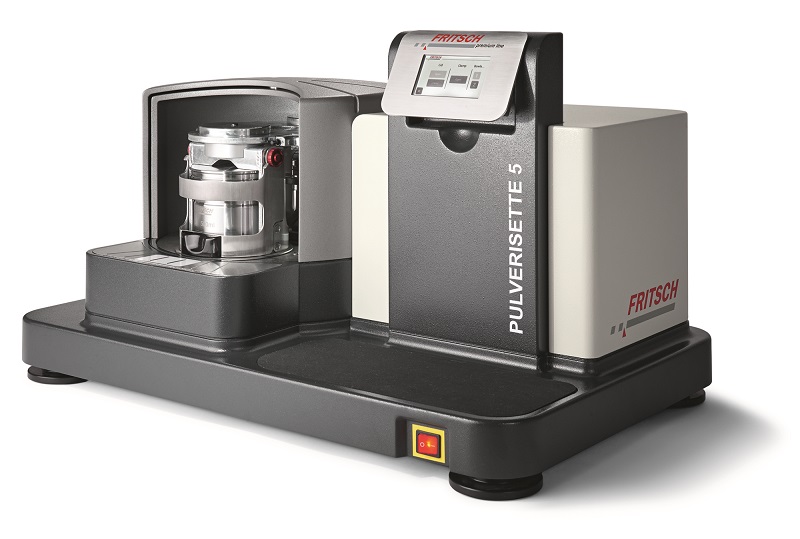

High Energy Planetary Ball Mill Pulverisette 5 Premium

$1The High Energy Planetary Ball Mill Pulverisette 5 PREMIUM with 2 working stations is the ideal mill for fast, wet or dry, grinding of larger sample quantities down to the nanometer range, with the highest safety standards.

Crushers, Pulverizers, Grinders

Planetary Mono Mill Pulverisette 6

$0The Planetary Mono Mill Pulverisette 6 is recommended for extremely rapid, batch grinding of hard to soft material, dry or in suspension, down to colloidal fineness. It is also an ideal laboratory instrument for mixing and homogenising of emulsions.

Crushers, Pulverizers, Grinders

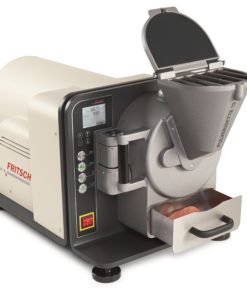

High-Tech Disc Pulverizer Pulverisette 13 Premium

$1The Laboratory Disc Pulverizer Pulverisette 13 Premium Line is designed for batch or continuous fine grinding of hard-brittle to medium-hard solids, down to 50µm.

Crushers, Pulverizers, Grinders

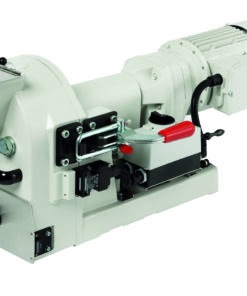

Universal Cutting Mill Pulverisette 19

$0The Universal Cutting Mill Pulverisette 19 is dedicated to grinding dry, soft to medium-hard, samples as well as fibrous materials and plastics.

Crushers, Pulverizers, Grinders

Laboratory Disc Pulverizer Pulverisette 13

$0The Laboratory Disc Pulverizer Pulverisette 13 is designed for batch or continuous fine grinding of hard-brittle to medium-hard solids.

Crushers, Pulverizers, Grinders

Laboratory Mini Mill Pulverisette 23

$0The Mini Ball Mill Pulverisette 23 is used for fine grinding of small quantities of dry samples or solids in suspensions, as well as mixing and homogenisation of emulsions.

Crushers, Pulverizers, Grinders

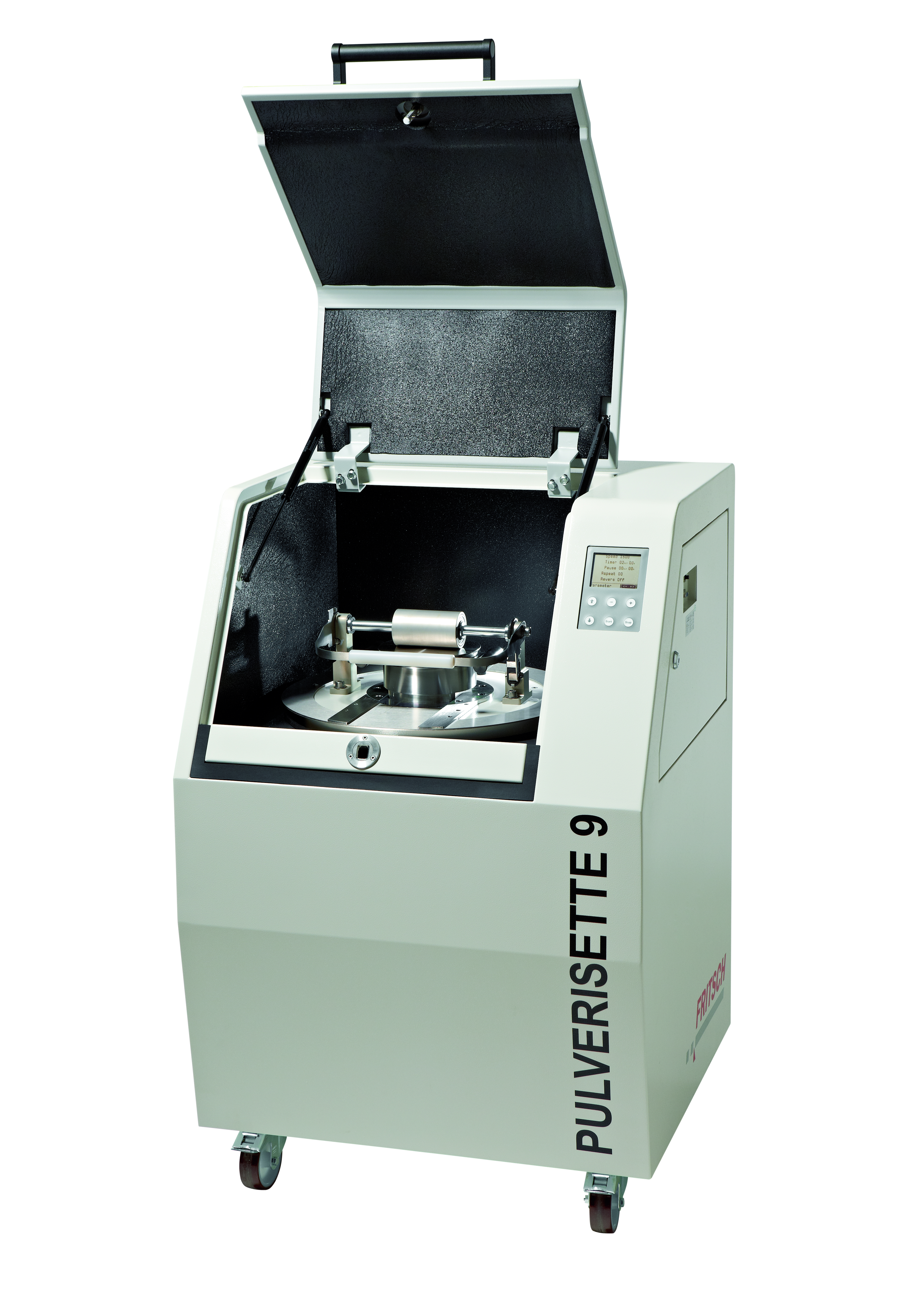

Laboratory Vibrating Cup Mill Pulverisette 9

$0The Ring & Puck Mill Pulverisette 9 is designed for extremely fast pulverizing (speed up to 1500 rpm) of hard, brittle and fibrous laboratory samples, dry or in suspension, down to analytical fineness.

Crushers, Pulverizers, Grinders

Laboratory Vibratory Micro Mill Pulverisette 0

$0The Micro Mill Pulverisette 0 is designed for fine grinding of dry laboratory samples or solids in suspension, and for homogenisation of emulsions or pastes.