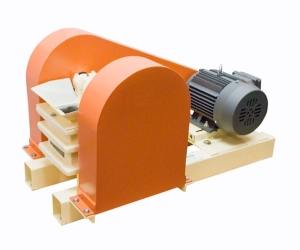

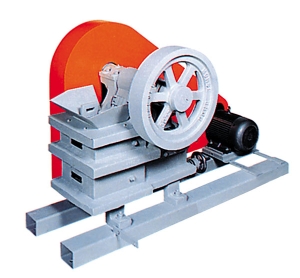

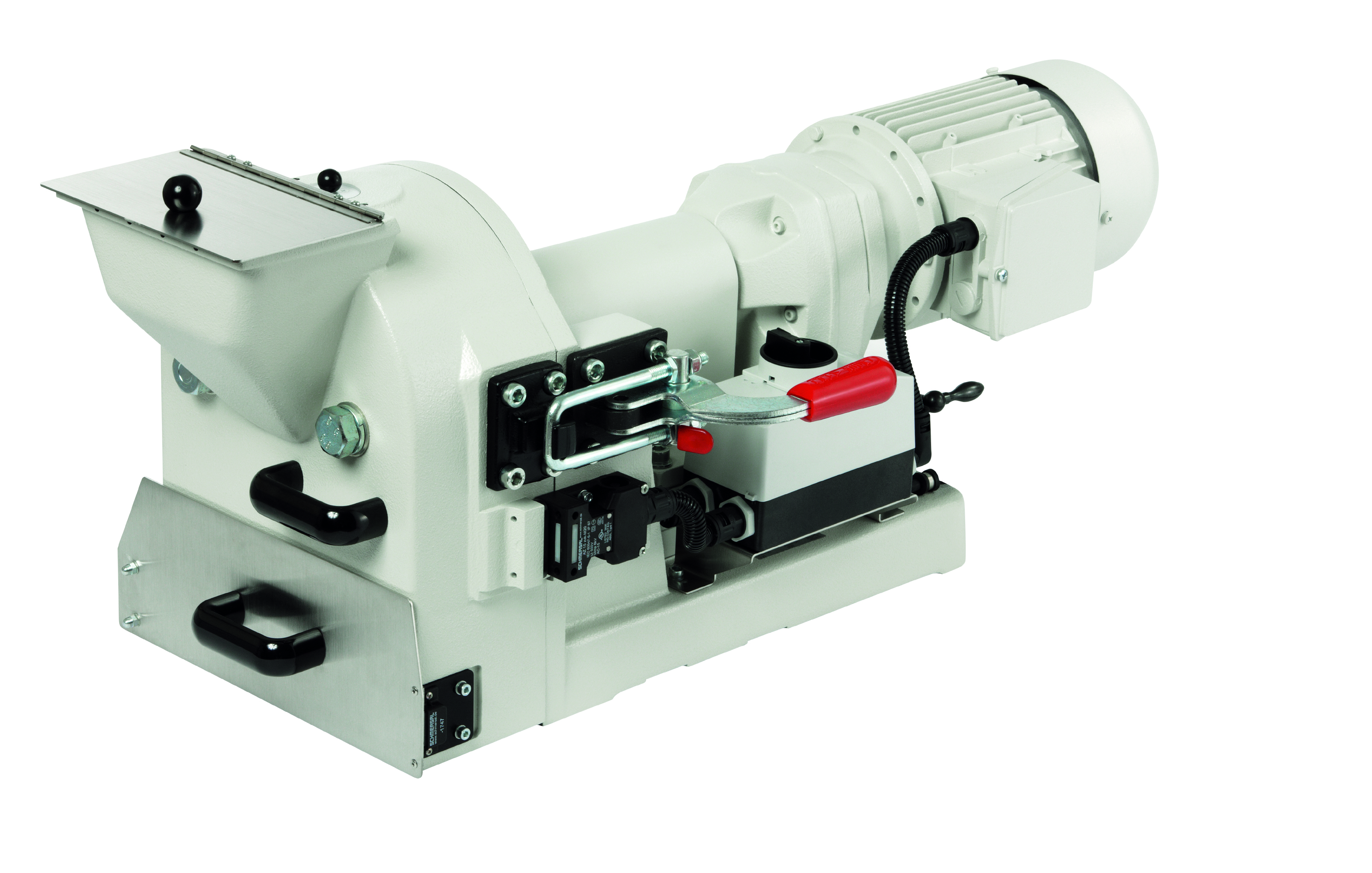

Morse ® Heavy-duty Jaw Crushers

Heavy-duty Morse Jaw Crushers are recommended for applications requiring high throughput and/or oversize feed.

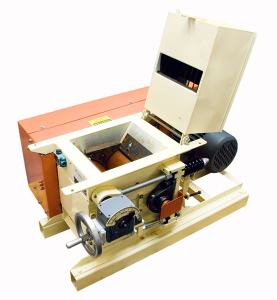

These high power Morse Jaw Crushers have heavy cast frames and flywheels. Guards for belts and flywheels are included as standard. Eccentric overhead action and corrugated jaw plates work together to force-feed material and avoid back-flow or “pop out” of particles as often occurs with units having smooth jaw plates. Particle size down to less than 1/4in (6.4mm) is set via hand wheel adjustment of a single toggle. Jaw plates are reversible for extended life. Crushing rates vary with hardness and size of feed.

Application: mining and metallurgy, commercial and industrial laboratory as well as pilot plant and small scale production.

| Model | 1000 2.25×3.5’’ (6×9 cm) | 2000 4×6’’ (10×15 cm) | 3000 5×6’’ (13×15 cm) | 4000 8×8’’ (20×20 cm) |

| Maximum feed size | 38 mm (1.5’’) | 76 mm (3’’) | 101 mm (4’’) | 165 mm (6.5’’) |

| Final fineness | 6.3 mm (1/4’’) | 6.3 mm (1/4’’) | 6.3 mm (1/4’’) | 6.3 mm (1/4’’) |

| Maximum capacity | 150 kg/h (340 lb./h) | 270 kg/h (600 lb./h) | 590kg/h (1300 lb./h) | 1450 kg/h (3200 lb./h) |

| Dimensions (WxDxH) | 46x91x58 cm (18x36x23’’) | 61x107x61 cm (24x42x24’’) | 76x137x97 cm (30x54x38’’) | 99x185x97 cm (39x73x38’’) |

| Weight | 150kg (340 lb.) | 270kg (600 lb.) | 590kg (1300 lb.) | 1450kg (3200 lb.) |

Jaws made of tempered abrasion-resistant steel alloy

The powerful size reduction of the sample takes place in the Jaw Crusher under high pressure between one fixed and one movable corrugated jaw. The final fineness is easily set by adjusting the gap width between the crushing jaws. The ground sample automatically falls into a drawer for batch operation, or via a chute into a larger collection container for continuous operation.

- Powerful units with heavy-duty cast frame and fly wheels

- Meet and exceed requirements for a pilot plant

- Delivers two crushing blows per revolution to speed crushing

Related products

Crushers, Pulverizers, Grinders

Universal Cutting Mill Pulverisette 19

$0The Universal Cutting Mill Pulverisette 19 is dedicated to grinding dry, soft to medium-hard, samples as well as fibrous materials and plastics.

Crushers, Pulverizers, Grinders

Laboratory Mini Mill Pulverisette 23

$0The Mini Ball Mill Pulverisette 23 is used for fine grinding of small quantities of dry samples or solids in suspensions, as well as mixing and homogenisation of emulsions.

Crushers, Pulverizers, Grinders

Laboratory Disc Pulverizer Pulverisette 13

$0The Laboratory Disc Pulverizer Pulverisette 13 is designed for batch or continuous fine grinding of hard-brittle to medium-hard solids.

Crushers, Pulverizers, Grinders

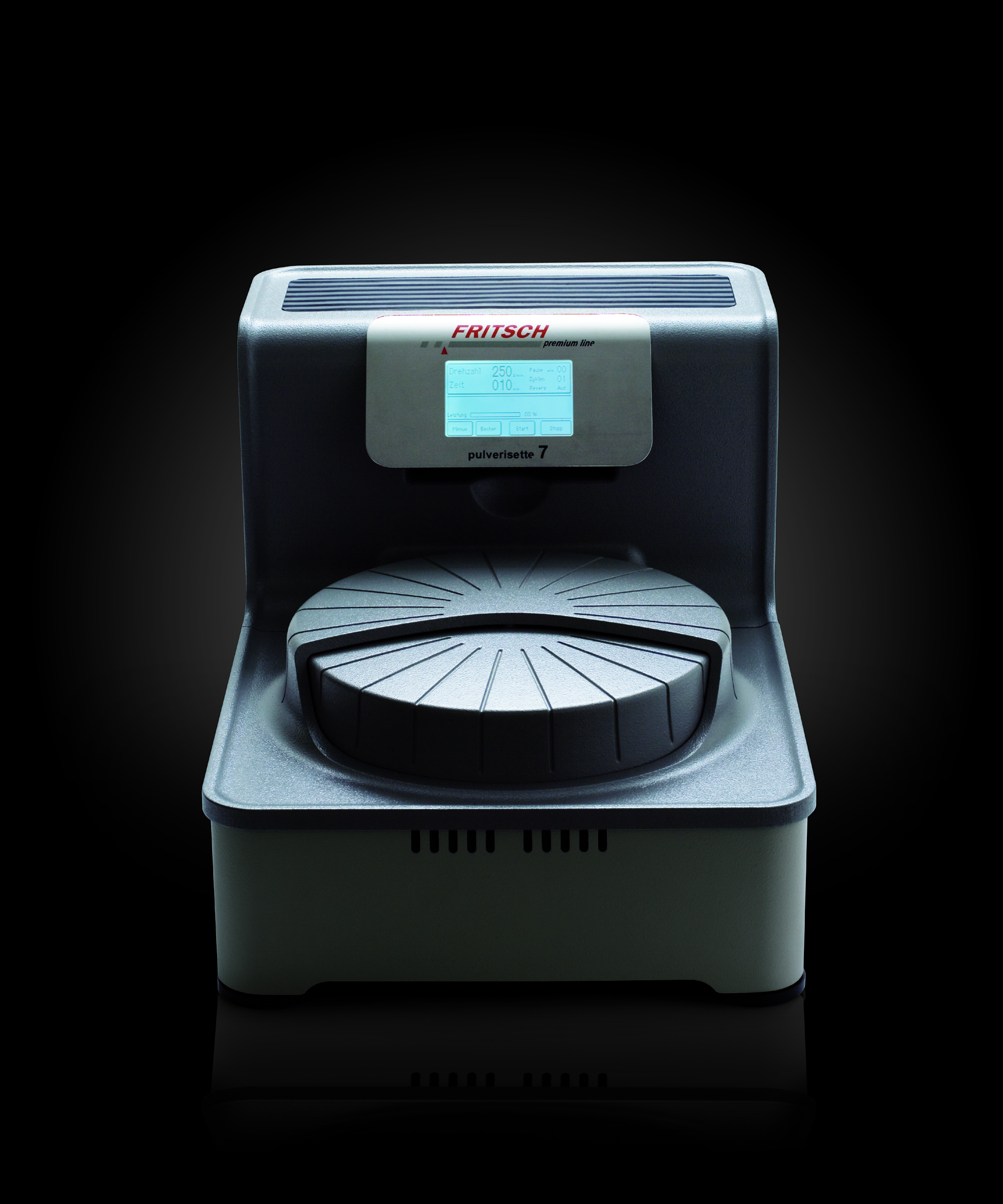

Nano Range Planetary Mill Pulverisette 7 Premium

$0Thanks to the high rotational speed of up to 1100 rpm for the main disc, this high-tech Planetary Mill, Pulverisette 7 Premium, easily grinds down to the nanometer range.

Crushers, Pulverizers, Grinders

Marcy® Double Roll Crushers

$1The Marcy Double Roll Crusher meets your requirements for intermediate crushing of friable rock or rock-like materials

Crushers, Pulverizers, Grinders

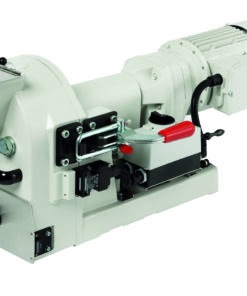

Laboratory Jaw Crusher Pulverisette 1

$0This Laboratory Jaw Crusher is designed for fast and effective pre-crushing of very hard, hard, medium-hard, and brittle materials, even ferrous alloys.

Crushers, Pulverizers, Grinders

Laboratory Cutting Mill Pulverisette 15

$0This Laboratory Cutting Mill is recommended for size reduction of dry sample material with soft to medium-hard consistency, for fibrous materials or cellulose materials.

Crushers, Pulverizers, Grinders

Laboratory Vibratory Micro Mill Pulverisette 0

$0The Micro Mill Pulverisette 0 is designed for fine grinding of dry laboratory samples or solids in suspension, and for homogenisation of emulsions or pastes.