Industrial Scale Bioreactors / Fermenters I Series

The Bioreactors – Fermenters of the I Series are highly automated production fermentation systems, available from 300 liters up to 30 m3, fully customized.

The control system technology permits the linking of several units by ETHERNET, for the eventual connection to the supervision system.

The Bioreactors – Fermenters of the I series are highly automated fermentation systems, available from 300 liters up to 30 m3, (10.5-1,060 cu. ft.), fully customized. The control system technology permits the linking of several units by ETHERNET, for the eventual connection to the supervision system.

This option is effective in case of installations on the line composed of different production units, also when complete production lines are realized, in which different parts can be placed in connection, thus being globally automated.

Leonardo 3.0 smart controller for pilot and industrial plants

Home page with Multi-level password protection.

Synoptic page with manual operation of all the actuators (pumps, valves etc.).

Controller page to easily view set points, current values and control mode, to set up customized PID (or use factory defaults) and alarm limits.

Leonardo 3.0 is able to manage different phases of the fermentation process: stand by phase for cleaning procedures or maintenance, fully automatic sterilization program (with media or empty), before cultivation (automatic phase after sterilization managing the pre-inoculum) and cultivation with control modes set up: set point maintenance, set point profiles and cascade.

Continuous trend graph representation to track, print and export data on up to 4 process and set point variables. Different dynamic zooms and configurations in a time frame that can be set interactively.

Producing set point profiles of the variables over time.

Pumps Configurator.

On line parameters calibration.

PID setting

USB connection for free data extracting.

Remote control for after sale assistance. 100% assistance from our office.

Possibility of saving several recipes for repeat usage.

Attribution to the variables of maximum and minimum values to act as alarm thresholds. SMS alarm service through internal modem.

Connection via Ethernet to other fermenters, connected instruments and supervision computers.

Print-out of hard copy of each screen.

| Description | Standard | Optional |

| Vessel | Stainless steel 316 L grain 240 | Special alloys Mirror polished |

| Heating circuit | Closed circuit, galvanized steel, heat exchanger for steam | Stainless steel 316 L, electrical heater, heat exchanger for cooling circuits |

| Agitation | Bottom drive by belt, double mechanical seal | Top drive, Magnetic coupling |

| Mechanical seal | Silicium carbide, glycerin lubricated | Steam condensate lubricated |

| Stirrer | Blade stirrers, baffles | Airlift, draught tube |

| Inlet air | Auto sterile filter, ceramic filter | Separate filter, double filters, absolute filter, gas mixing station |

| Aeration | Submerse aeration | Surface aeration, bubble-free aeration |

| Ports | Standardized lid and side ports | Flexible location and number, special ports |

| Viewing glasses | Longitudinal and lid viewing glass with illumination | Flexible location and number |

| Exhaust air | Ceramic filter | Absolute filter, reflux cooler, foam destruction, incinerator |

| Inoculation | Inoculation port | Fixed piping, transfer concepts |

| Sampling | Manual sampling valve | Pneumatic valve, contained sampling valve, valve with steel bellow, cell-free sampling system |

| Harvest | Manual harvest valve with steel bellows | Pneumatic harvest valve, fixed piping, transfer concept |

| Media addition | Needle connection through lid | Dosage valve, coupling, fixed piping, transfer concepts |

| Sterilization | Manual sterilization of auto sterile filter and exhaust air valve | Automatic sterilization of auto sterile filter and exhaust air valve |

- Design and construction for a user-friendly and sturdy high-tech plant

- Fulfils ASME and cGMP/FDA-regulations

- Control system allows the linking of several units

Related products

Fermentor, Bioreactor

Bench-Top Mini Bioreactors Fermenters

$1These mini Bioreactors Fermenters are ideal for performing small-scale trial runs, experiment configurations, as well as analyzing and optimizing cultivation parameters.

Fermentor, Bioreactor

M series SIP laboratory bioreactors / fermenters

$1M Series are steam in place bioreactors – fermenters available in a range of volumes from 30 up to 200 liters.

Fermentor, Bioreactor

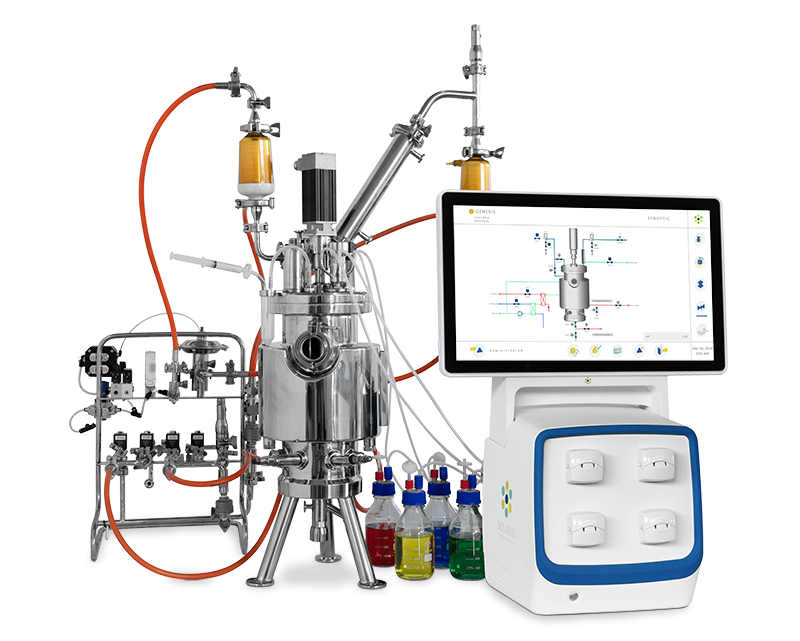

Genesis Sterilizable In Place Bench-Top Bioreactors – Fermenters

Genesis Sterilizable In Place Bench-Top Bioreactors – Fermenters

$1Automatic sterilization through electric heaters (no need for an external steam source) or alternatively by steam. Total voulme from 7.5 up to 20 liters.

Fermentor, Bioreactor

Jupiter Autoclave Bench-Top Bioreactors – Fermenters

$1These Bench-top Bioreactors – Fermenters represent the ideal solution for all necessities in the field of research, teaching and small scale production due to their flexibility and simplicity of use.

Fermentor, Bioreactor

Elara Laboratory Bench-Top Photo Bioreactor

$1For photosynthesis process research of phototrophic organisms such as Micro Algae, Plant Cells, Cyanobacteria, Moss. Standard 4L vessel or Flat Panel (flate plate) 1.6L

Fermentor, Bioreactor

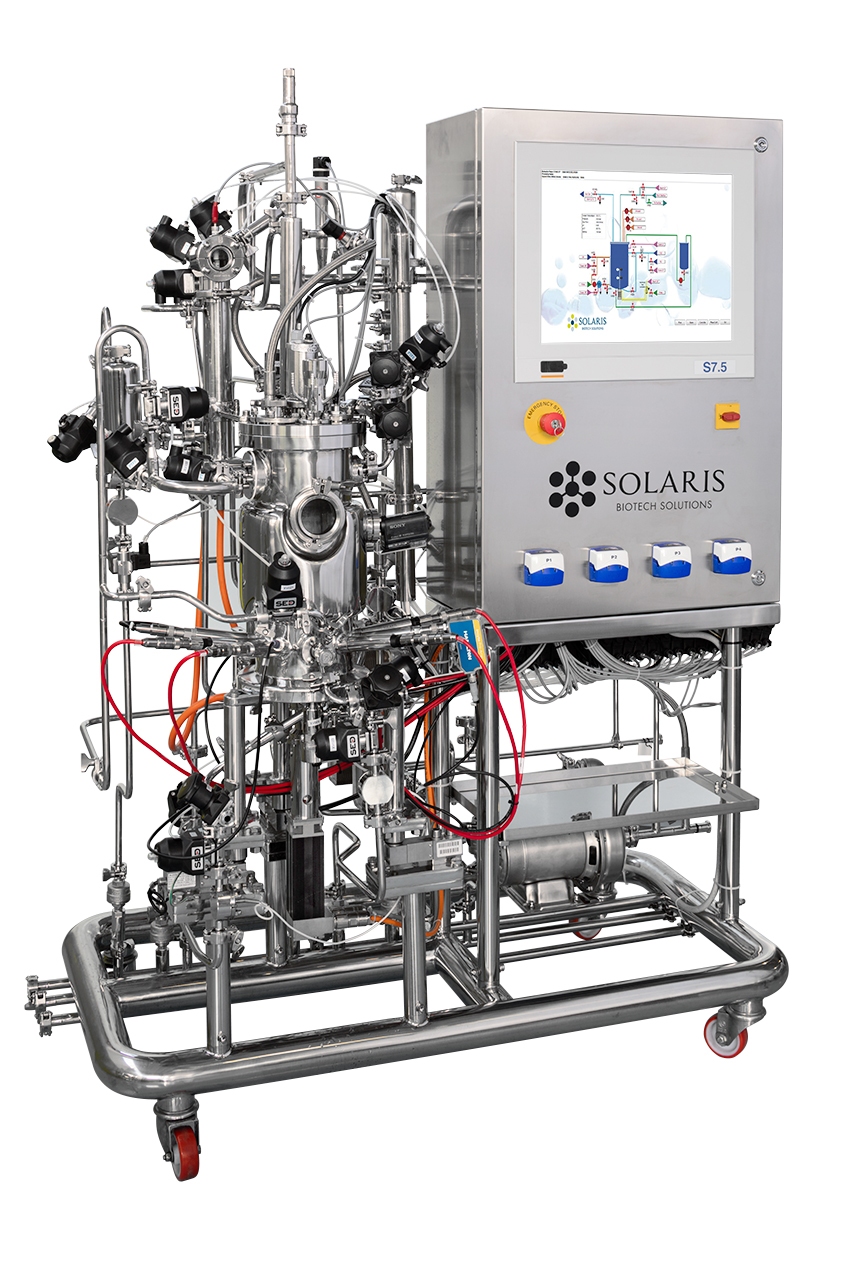

S Series Sterilizable In Place Pilot Scale Bioreactors / Fermenters

S Series Sterilizable In Place Pilot Scale Bioreactors / Fermenters

$1The S series pilot scale bioreactors / fermenters are designed for research and development in process scale-up. Culture vessels from 5 to 200L.

Fermentor, Bioreactor

LB Series Dairy Pilot Bioreactors / Fermenters

$1The LB series fermenters are the result of an innovative project that Solaris developed together with Regione Lombardia through ERSAF, the dairy farming local scientific organization.