Laboratory Jaw Crusher Pulverisette 1

This Laboratory Jaw Crusher is designed for fast and effective pre-crushing of very hard, hard, medium-hard, and brittle materials, even ferrous alloys.

The Laboratory Jaw Crusher Pulverisette 1 is recommended for intermittent or continuous pre-crushing of coarse materials.

The maximum feed size is approximately 60 mm (model I) or 95 mm (model II). The maximum throughput is

140 kg/h (model I) or 200 kg/h (model II). The optimum fineness depends on the gap width adjustment for setting the distance between the crushing jaws – and therefore setting the final fineness, which is approximately

d50 = 15 mm (maximum gap width) d50 = 1 mm (minimum gap width)

The funnel of the FRITSCH Jaw Crusher PULVERISETTE 1 classic line is particularly accessible, quickly and easily filled even with larger sample quantities and easy to clean.Its design enables the crushed material to be automatically conveyed into the crushing chamber – blockages are practically impossible.

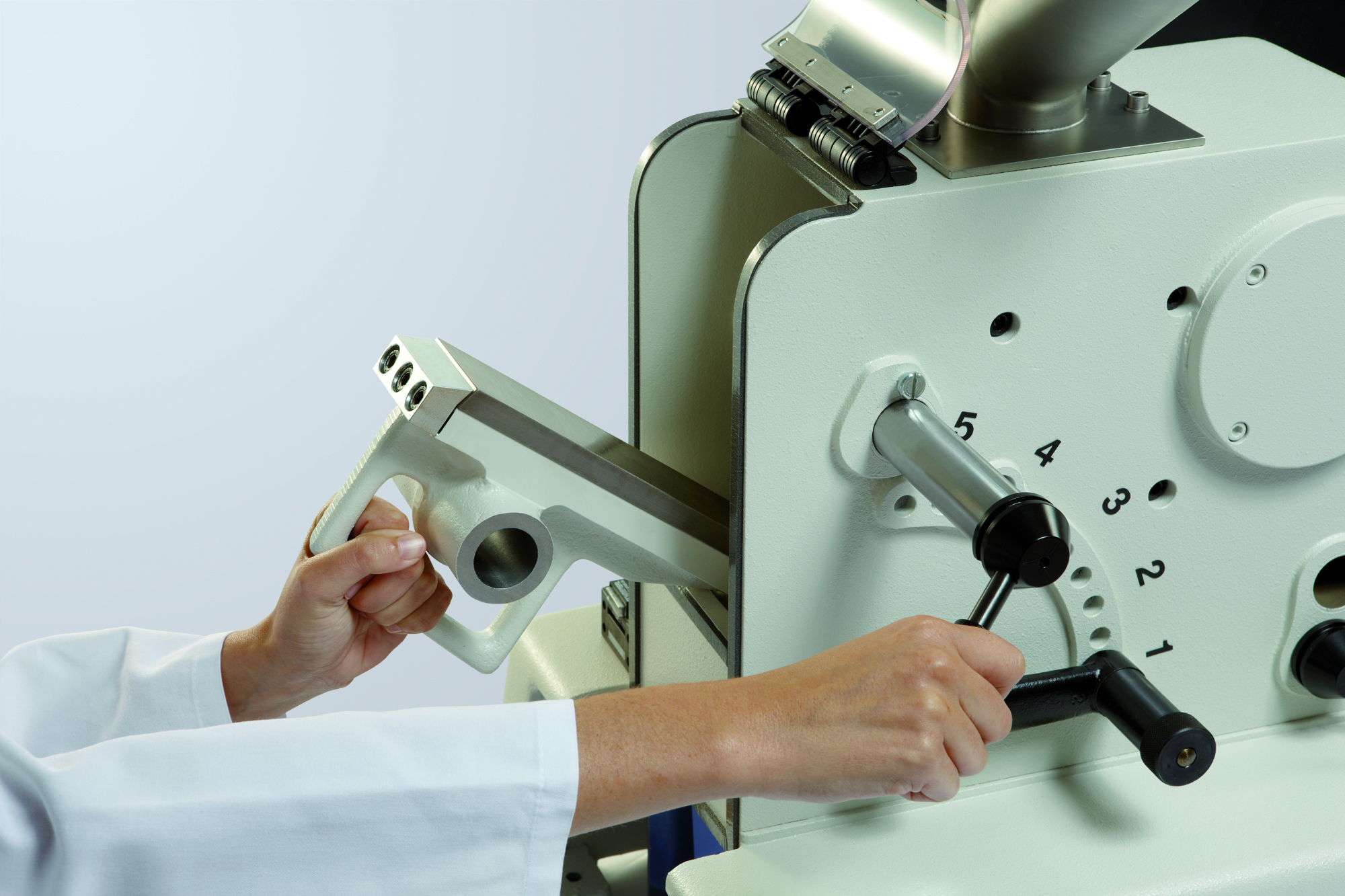

The crushing jaws can be removed for cleaning quickly and easily with just 2 hand motions.

Especially safe and dust-free: the enclosed grinding chamber prevents users from reaching inside and ensures a safe and dust-free operation of all moving parts. An integrated connection makes it very simple to combine the instrument with a dust exhaust system for automatic removal of the fine dust arising during grinding. The dust exhaust system is also very useful when cleaning the grinding parts.

The crushing jaws and lateral support walls of the Jaw Crusher Pulverisette 1 classic line are available in 6 different materials in order to avoid undesired contamination due to material abrasion. The standard version is equipped with fixed and movable crushing jaws as well as lateral support walls made of tempered steel.

Normally, crushing jaws and support walls of the same material are used. Since the lateral support walls are subject to low stresses, however, the standard lateral support walls made of tempered steel can often be retained.

For completely iron-free pre-crushing of medium-hard brittle samples, for example in the ceramics industry, we can equip your Jaw Crusher Pulverisette 1 classic line with crushing jaws made of zirconium oxide, lateral support walls in zirconium oxide or aluminium, and with a special PVC funnel. So you will have absolute protection against iron contamination, such as for dental ceramics.

Applications: mining and metallurgy, chemistry, geology and mineralogy, glass industry, ceramics, rocks and soils.

| Maximum feed size: | 60 mm (2-1/2’’) model I, 95 mm (3-3/4’’) model II |

| Final fineness: | 1-15 mm (16 mesh – 5/8’’) |

| Maximum capacity: | 140 kg/h (model I) – 200 kg/h (model II) |

| Grinding materials: | Tempered steel, stainless steel, chromium-free steel, manganese steel, tungsten carbide, zirconium oxide, aluminium |

| Dimensions (WxDxH): | 40x80x80 cm (16x32x32’’) |

| Weight: | 177 kg (390 lbs.) model I – 205 kg (450 lbs.) model II |

- Certified safety (CE mark) – optional CSA approval for Canada

- 2-year warranty

- Combinable with the Disc Pulverizer PULVERISETTE 13

The powerful size reduction of the sample takes place in the Jaw Crusher under high pressure between one fixed and one movable crushing jaw in an enclosed grinding chamber. The final fineness is easily set from the outside with the 10-stage adjustable gap width between the crushing jaws. The ground sample automatically falls into a drawer for batch operation, or via a chute into a larger collection container for continuous operation, or directly into the Disc Pulveriser Pulverisette 13 for fine grinding.

- Very fast, uniform crushing

- Fast and easy cleaning

- Extremely robust, even for very hard materials

- German quality

Related products

Crushers, Pulverizers, Grinders

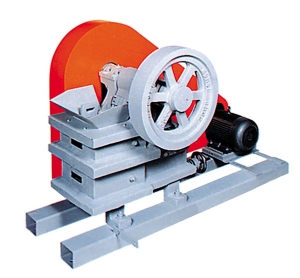

Morse ® Heavy-duty Jaw Crushers

$1Heavy-duty Morse Jaw Crushers are recommended for applications requiring high throughput and/or oversize feed.

Crushers, Pulverizers, Grinders

Mortar Grinder Pulverisette 2

$0The Automatic Mortar Grinder Pulverisette 2 is ideal for universal grinding of medium-hard-brittle to soft-brittle materials (dry or in suspension) to analytical fineness, as well as for formulation and homogenisation of pastes and creams at laboratory scale.

Crushers, Pulverizers, Grinders

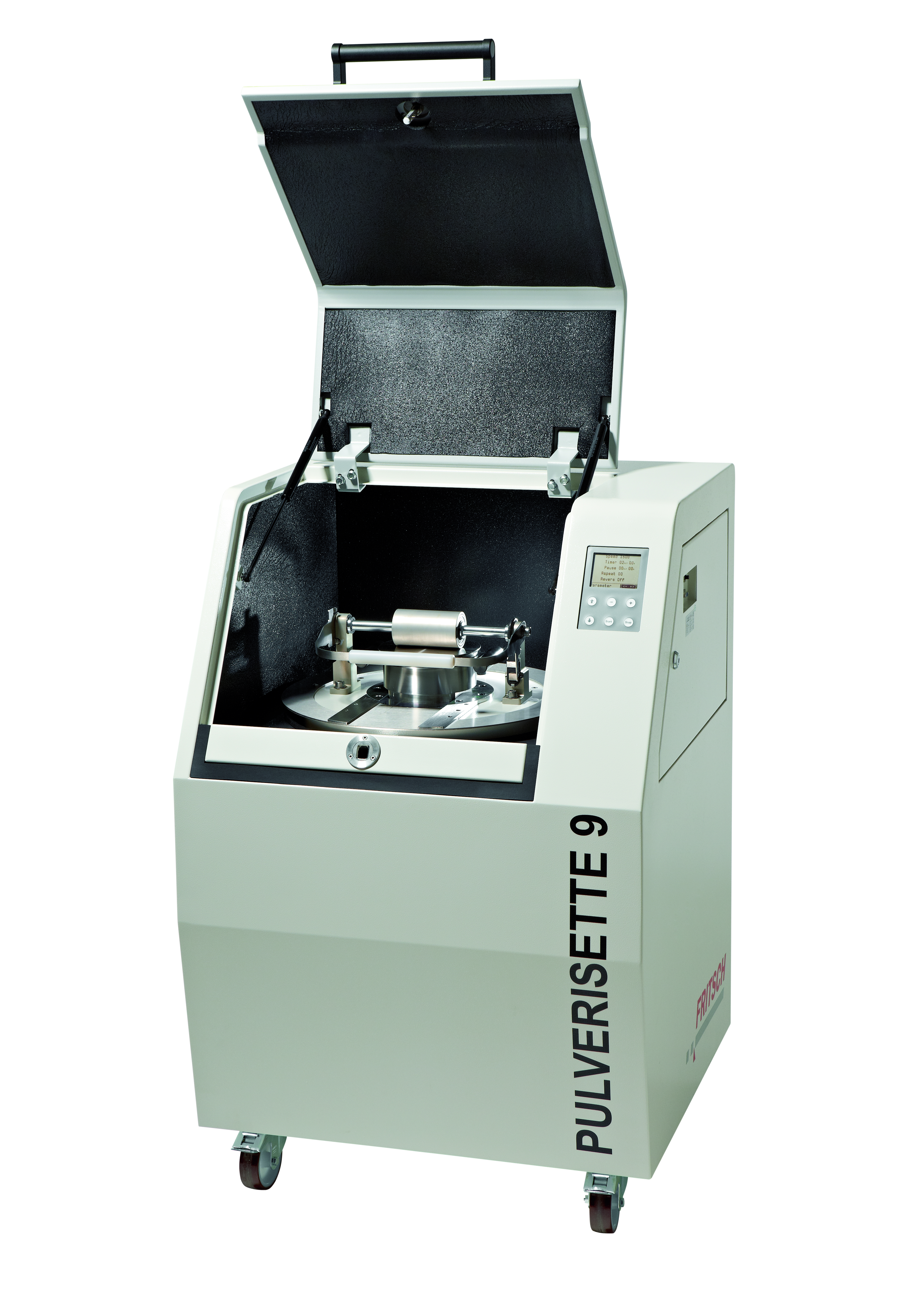

Laboratory Vibrating Cup Mill Pulverisette 9

$0The Ring & Puck Mill Pulverisette 9 is designed for extremely fast pulverizing (speed up to 1500 rpm) of hard, brittle and fibrous laboratory samples, dry or in suspension, down to analytical fineness.

Crushers, Pulverizers, Grinders

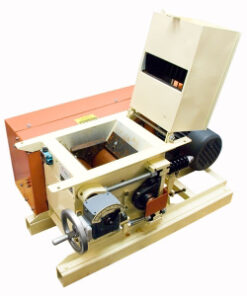

Marcy® Double Roll Crushers

$1The Marcy Double Roll Crusher meets your requirements for intermediate crushing of friable rock or rock-like materials

Crushers, Pulverizers, Grinders

Cutting Mill Pulverisette 19 for Cannabis Processing

$1The Pulverisette 19 Universal Cutting Mill System has been optimized for Cannabis Processing.

Crushers, Pulverizers, Grinders

Variable Speed Rotor Mill Pulverisette 14 Premium

$1The Variable Speed Rotor Mill Pulverisette 14 Premium is a versatile, powerful mill for the fast grinding of medium-hard, brittle as well as fibrous materials and temperature sensitive samples.

Crushers, Pulverizers, Grinders

Planetary Mill Pulverisette 4 for mechanical alloying and mechanical activation

Planetary Mill Pulverisette 4 for mechanical alloying and mechanical activation

$1The Vario Planetary Mill Pulverisette 4 is ideal for mechanical activation and alloying. It offers the freedom to program all grinding parameters through PC software to achieve the desired effect on the sample.

Crushers, Pulverizers, Grinders

Planetary Ball Mill Pulverisette 5

$0The Planetary Ball Mill Pulverisette 5 allows fast and very fine grinding of hard to soft material, dry or in suspension, down to colloidal fineness. It can also be used for mixing and homogenising of emulsions and pastes.

Grinding capacity of up to 8 samples per operation.