Cross Beater Mill Pulverisette 16

Suitable for grinding medium-hard, brittle materials.

The cross beater mill Pulverisette 16 is universally used in the chemical and ceramic industries; in mining and metallurgy, and in agriculture for the preparation of soil samples. It is especially suitable for the grinding of medium-hard, brittle materials. In the laboratory, the Pulverisette 16 is used for pre-crushing and fine crushing.

Applications : leaves, grain, resins, cellulose, chemicals, dried fruits, peat, seeds, dried plants, animal feed, salt, pellets, coal, porcelain clay, spices, gypsum, drugs, potash, tablets, slag, minerals, ash, stone and soils (bauxite, limestone, dried clay, etc.), synthetic resins, pyrite, cement clinker, coke, ores, refractory materials.

| Maximum feed size | 25 mm |

| Final fineness | <0.1 to 10 mm (depends on sieve insert) |

| Maximum capacity | 80 L/h |

| Grinding materials | Cast iron or Stainless Steel |

| Dimensions (WxDxH) | Bench top instrument or on stand 50x50x58 cm (20x20x23’’) |

| Weight | 45 kg (100 lbs.) |

Certified safety (CE mark) – optional CSA approval for Canada 2-year warranty

Impact, friction, shearing

Comminution in the Cross Beater Mill takes place through impact, friction and shearing forces. The feeding funnel guides the grinding material directly into the centre of the grinding chamber, where it is taken up by the cross beater and comminuted between the impact plates of the cross beater and the teeth of the grinding insert. The selected bottom sieve determines the final fineness. The rotating cross beater also creates an airflow through the funnel that accelerates the discharging of the ground sample into the collecting vessel. The supplied filter hose can be integrated here to effectively reduce the release of fine dust.

Highest operational safety

If the quick-clamping lock is opened unintentionally, a safety switch activates the motor brake so that the rotor comes to a stop in less than 0.5 seconds.

- 1.1 kW brake motor, 2000 to 4,000 rpm with maintenance-free direct drive

- Toothed grinding tools of cast iron or stainless steel

- Easy cleaning with grinding tools simple to remove

- German quality

Related products

Crushers, Pulverizers, Grinders

Planetary Mono Mill Pulverisette 6

$0The Planetary Mono Mill Pulverisette 6 is recommended for extremely rapid, batch grinding of hard to soft material, dry or in suspension, down to colloidal fineness. It is also an ideal laboratory instrument for mixing and homogenising of emulsions.

Crushers, Pulverizers, Grinders

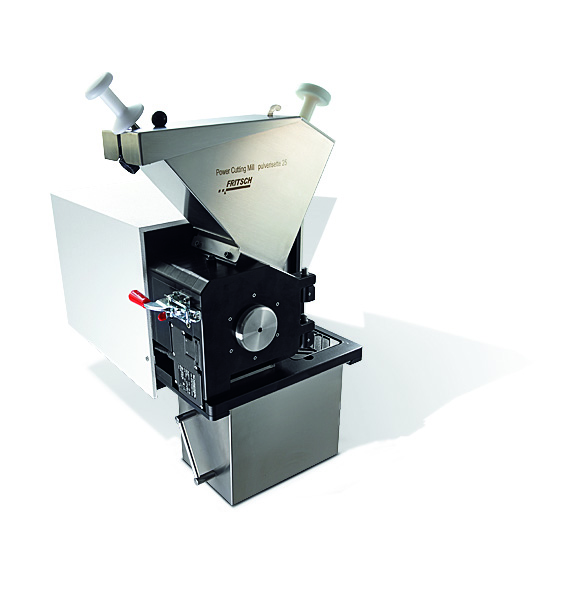

Power Cutting Mill Pulverisette 19 LARGE

$1The Pulverisette 19 Large is a powerful cutting mill for the coarse grinding of dry, soft to medium-hard or fibrous materials and plastics.

Crushers, Pulverizers, Grinders

Knife Mill Blender Pulverisette 11

$1The Knife Mill Homogenizer Pulverisette 11 is the ideal Laboratory Mixer for fast size reduction and homogenization of Food samples

Crushers, Pulverizers, Grinders

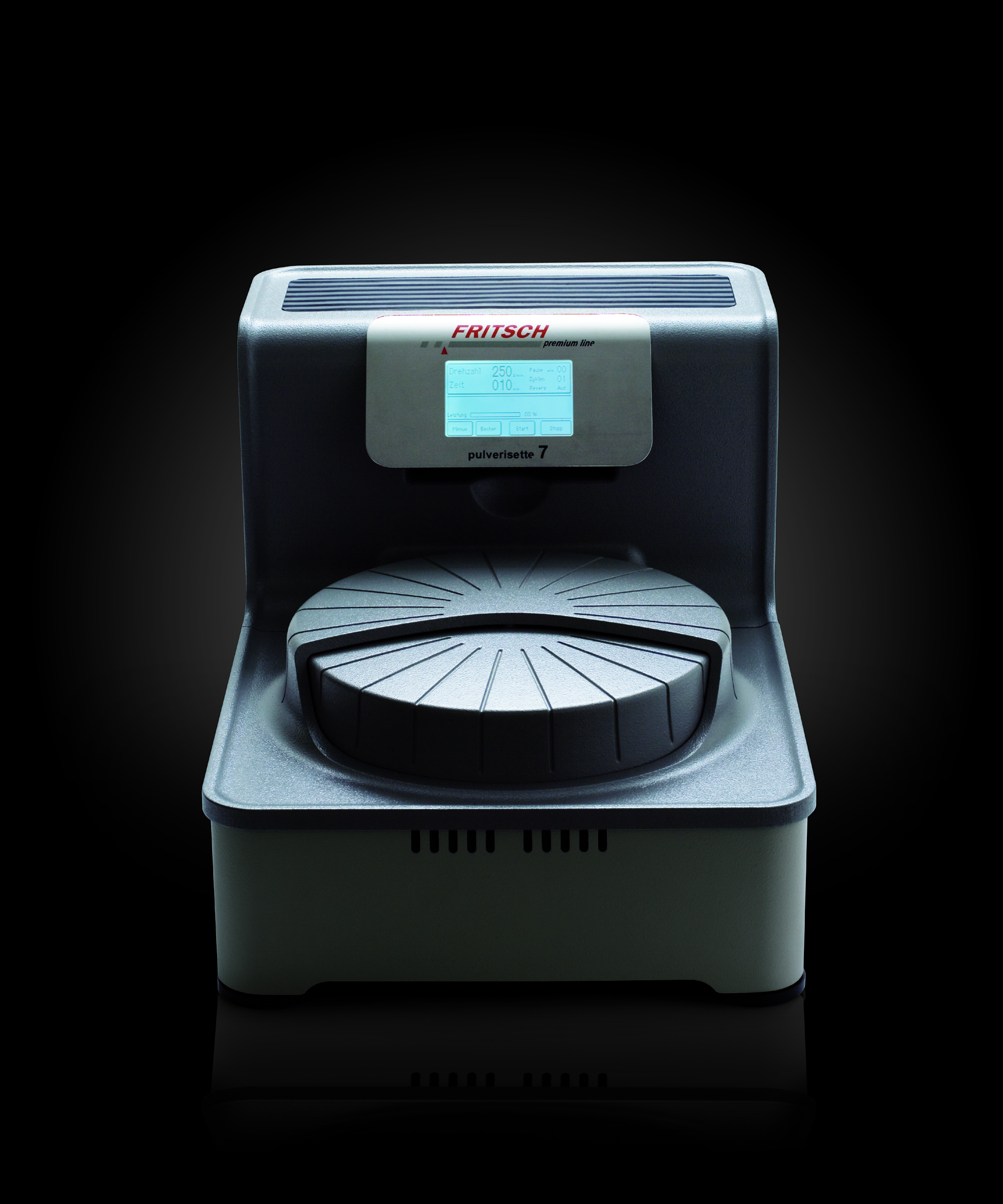

Nano Range Planetary Mill Pulverisette 7 Premium

$0Thanks to the high rotational speed of up to 1100 rpm for the main disc, this high-tech Planetary Mill, Pulverisette 7 Premium, easily grinds down to the nanometer range.

Crushers, Pulverizers, Grinders

Variable Speed Rotor Mill Pulverisette 14 Premium

$1The Variable Speed Rotor Mill Pulverisette 14 Premium is a versatile, powerful mill for the fast grinding of medium-hard, brittle as well as fibrous materials and temperature sensitive samples.

Crushers, Pulverizers, Grinders

Laboratory Jaw Crusher Pulverisette 1

$0This Laboratory Jaw Crusher is designed for fast and effective pre-crushing of very hard, hard, medium-hard, and brittle materials, even ferrous alloys.

Crushers, Pulverizers, Grinders

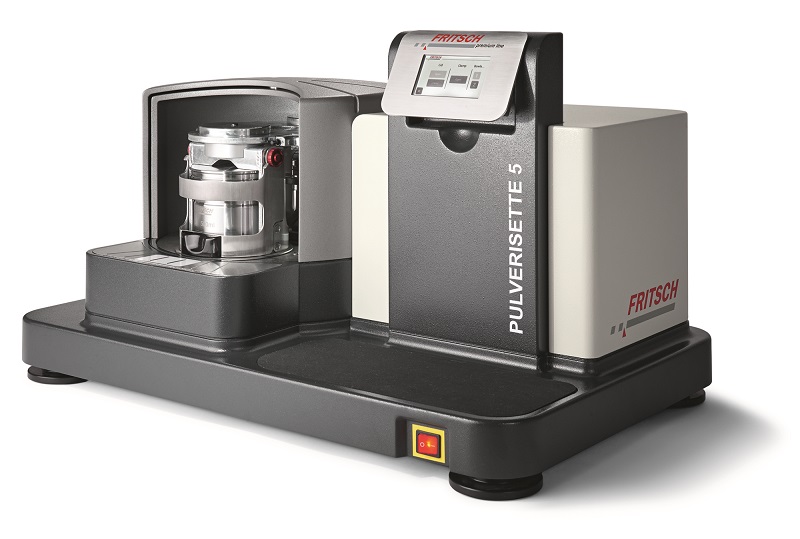

High Energy Planetary Ball Mill Pulverisette 5 Premium

$1The High Energy Planetary Ball Mill Pulverisette 5 PREMIUM with 2 working stations is the ideal mill for fast, wet or dry, grinding of larger sample quantities down to the nanometer range, with the highest safety standards.

Crushers, Pulverizers, Grinders

Laboratory Cutting Mill Pulverisette 15

$0This Laboratory Cutting Mill is recommended for size reduction of dry sample material with soft to medium-hard consistency, for fibrous materials or cellulose materials.