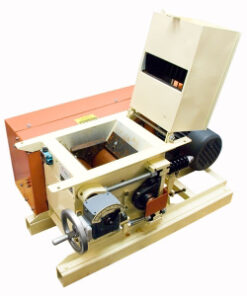

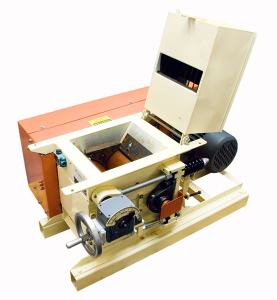

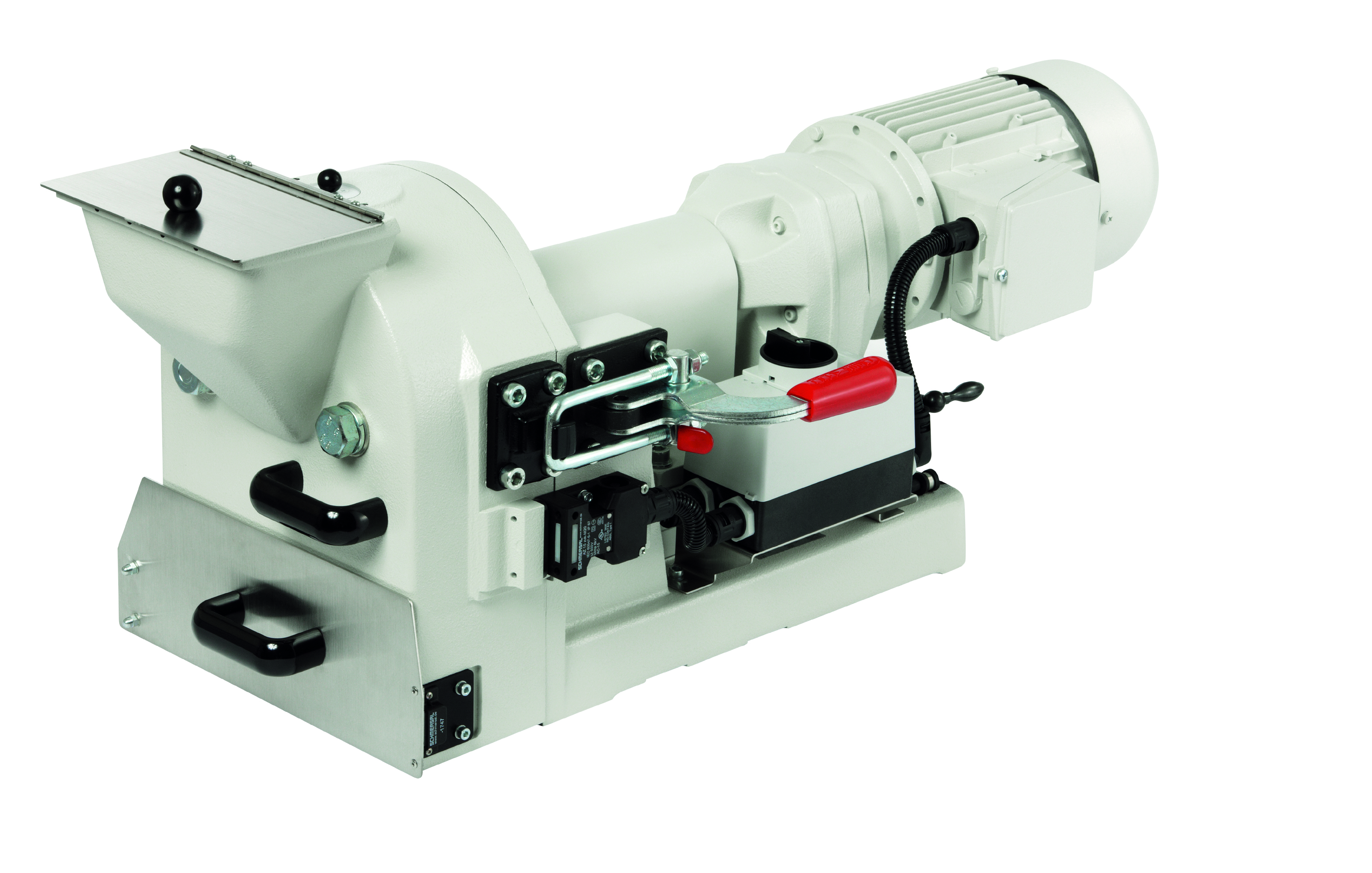

Mini Cutting Mill Pulverisette 29

This Mini Cutting Mill is recommended for size reduction of small samples such as grain, seeds or plastics and other low specific density products.

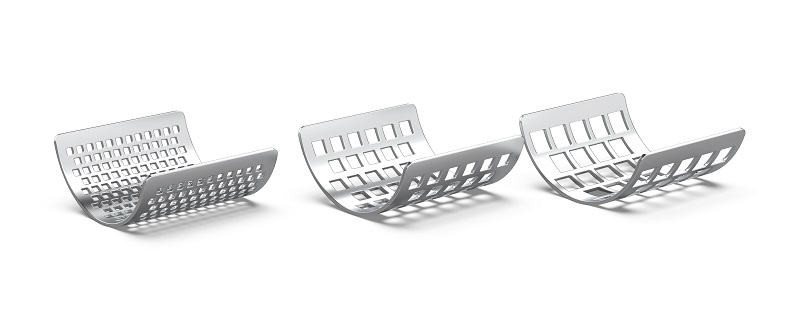

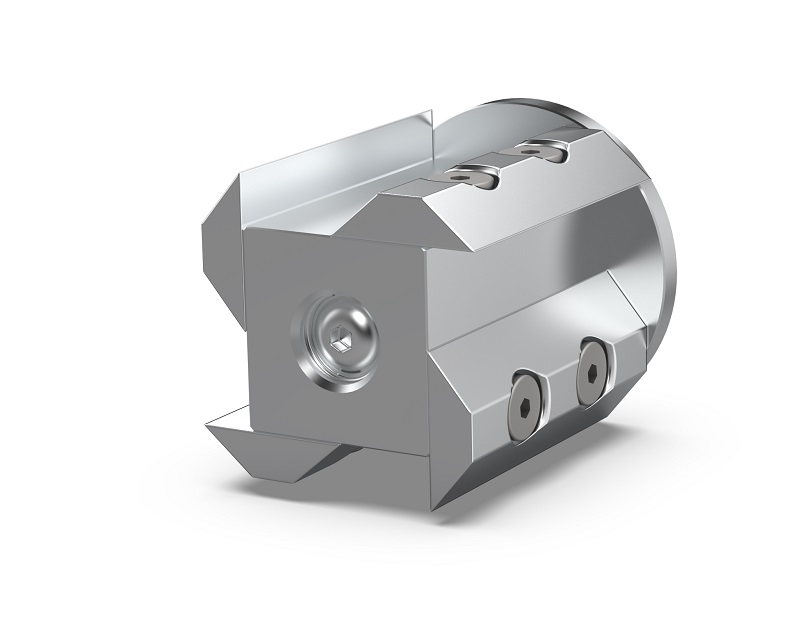

The Mini Cutting Mill Pulverisette 29 is designed for the size reduction of medium-hard, soft, tough, fibrous, tough-elastic and temperature sensitive materials such as grain, seeds or even plastics and other materials with a low specific density with reliable reproducible results. Due to the variable rotational speed adjustment between 500 and 6000 rpm you can fine tune the comminution process for each sample. The rotor with 4 straight cutting edges and fixed knives made of hardened stainless steel enable up to 48,000 cutting processes per minute. Various sieve inserts made of stainless steel 316L, with square or trapezoidal perforation enable you to achieve a final fineness of 0.25 to 6 mm.

Ideal for analysis of moisture, raw fibre and ash as well as for IR and NIR

Thanks to its variable rotational speed, the Pulverisette 29 comminutes especially grain and other seeds in an optimal way, and with almost no loss of moisture. It thus fulfils the essential requirement for the preparation of analytical samples in the area of feed and raw material sampling.

| Maximum feed size: | 25mm (1’’) |

| Final fineness: | 0.25 to 6 mm (depends on sieve insert) |

| Grinding materials: | Cutting knives hardened stainless steel |

| Dimensions (WxDxH): | Bench top instrument 27x35x34cm (11x14x14’’) |

| Weight: | 18 kg (40 lbs.) |

Certified safety (CE mark) and 2-year warranty – optional CSA approval for Canada

In the grinding chamber of the Mini Cutting Mill, four rotating knives slice up the grinding sample in combination with four fixed knives. The cut material remains in the grinding chamber until the desired final fineness is reached, at which point it is discharged through the sieve insert into the collecting vessel.

- Fast reproducible comminution

- Variable speed 500-6000 rpm, 48,000 cutting per minute

- Easy cleaning of grinding chamber and grinding parts

Related products

Crushers, Pulverizers, Grinders

Planetary Ball Mill Pulverisette 5

$0The Planetary Ball Mill Pulverisette 5 allows fast and very fine grinding of hard to soft material, dry or in suspension, down to colloidal fineness. It can also be used for mixing and homogenising of emulsions and pastes.

Grinding capacity of up to 8 samples per operation.

Crushers, Pulverizers, Grinders

Laboratory Marcy® Gyroll 6-inch & 10-inch Cone Crushers

$1The Gyroll Cone Crushers are recommended mining industry, for intermediate crushing of friable rock, feed of spiral concentration, concentration table or laboratory pulverizer.

Crushers, Pulverizers, Grinders

Variable Speed Rotor Mill Pulverisette 14 Premium

$1The Variable Speed Rotor Mill Pulverisette 14 Premium is a versatile, powerful mill for the fast grinding of medium-hard, brittle as well as fibrous materials and temperature sensitive samples.

Crushers, Pulverizers, Grinders

Marcy® Double Roll Crushers

$1The Marcy Double Roll Crusher meets your requirements for intermediate crushing of friable rock or rock-like materials

Crushers, Pulverizers, Grinders

Laboratory Disc Pulverizer Pulverisette 13

$0The Laboratory Disc Pulverizer Pulverisette 13 is designed for batch or continuous fine grinding of hard-brittle to medium-hard solids.

Crushers, Pulverizers, Grinders

Laboratory Vibratory Micro Mill Pulverisette 0

$0The Micro Mill Pulverisette 0 is designed for fine grinding of dry laboratory samples or solids in suspension, and for homogenisation of emulsions or pastes.

Crushers, Pulverizers, Grinders

Planetary Mill Pulverisette 4 for mechanical alloying and mechanical activation

Planetary Mill Pulverisette 4 for mechanical alloying and mechanical activation

$1The Vario Planetary Mill Pulverisette 4 is ideal for mechanical activation and alloying. It offers the freedom to program all grinding parameters through PC software to achieve the desired effect on the sample.

Crushers, Pulverizers, Grinders

Planetary Micro Mill Pulverisette 7

$0The Planetary Micro Mill Pulverisette 7 is designed for uniform, and extremely fine size reduction of very small samples of hard to soft material, dry or in suspension, down to colloidal fineness. Also designed for mixing and homogenising of emulsions or pastes.