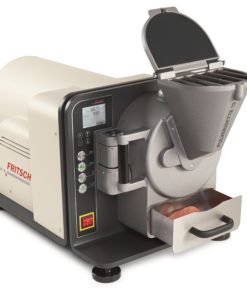

Planetary Mill Pulverisette 4 for mechanical alloying and mechanical activation

The Vario Planetary Mill Pulverisette 4 is ideal for mechanical activation and alloying. It offers the freedom to program all grinding parameters through PC software to achieve the desired effect on the sample.

The Pulverisette 4 Vario-Planetary Mill is capable of emulating conventional ball mills, precisely simulating the types of stress entailed and thus reproducing or optimising grinding processes. Due to the high flexibility available for selecting the grinding parameters, it is possible to achieve results unattainable with any other ball mill.

This is the ideal mill for mechanical activation and alloying. The main applications are in the field of materials research and wherever a powerful, innovative planetary mill is required.

When particles < 10 mm are fed in, a final fineness up to 0.1 μm can be achieved.

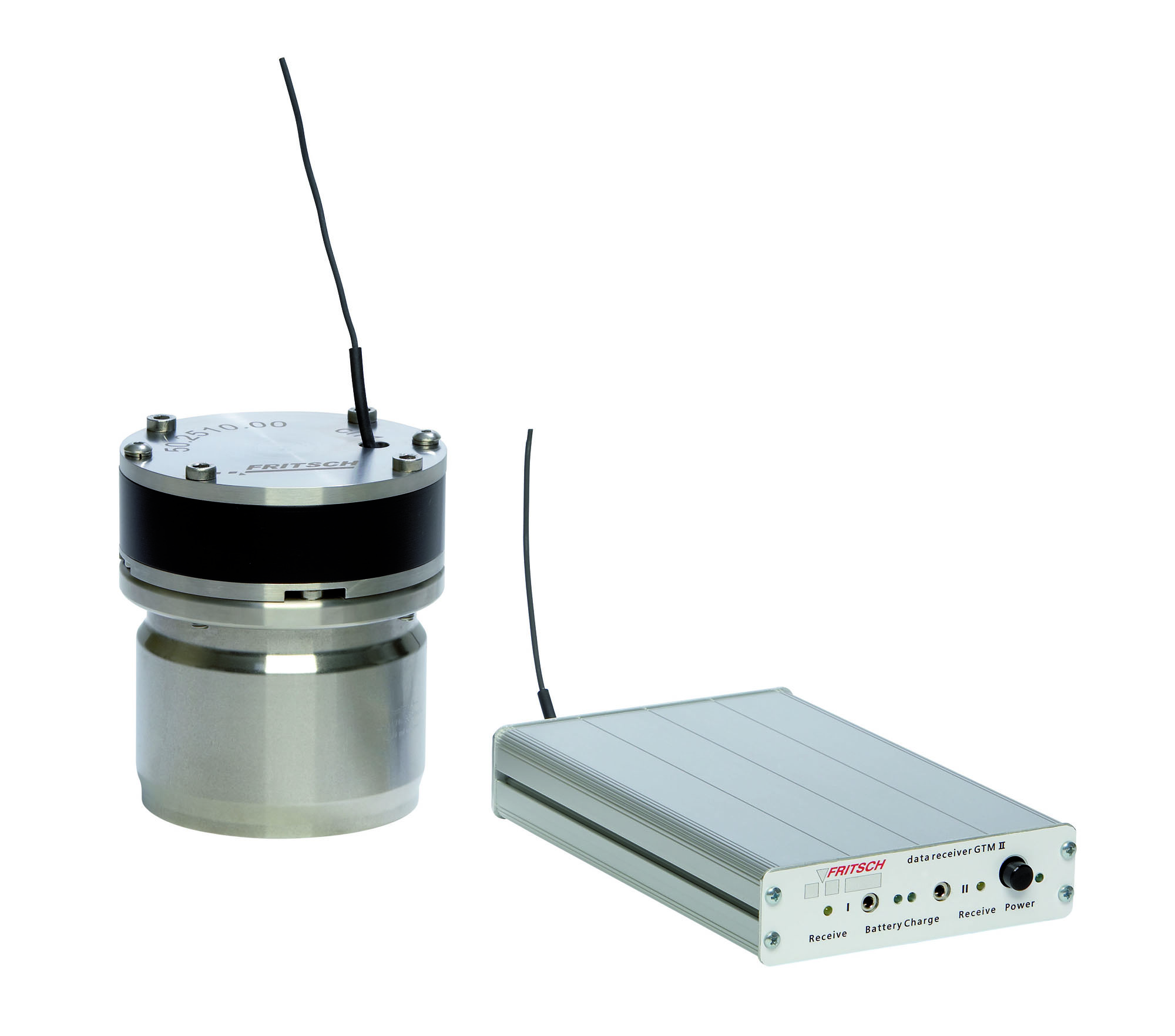

GTM – gas pressure and temperature measuring system

This system enables the vario-planetary mill to be converted into an analytical measuring system. Continual monitoring of gas pressure and temperature enables thermal effects, physical and chemical reactions (pressure increase or decrease) to be monitored in situ in the grinding bowl.

There is a radio transmitter in the lid of the grinding bowl and a receiver transfers the data to a computer.

Grinding in an inert atmosphere

– Using a special lid for the grinding bowl, material can also be ground in an inert atmosphere.

– If the grinding bowl needs to be filled in a glove box, the additional lock-system is available

| Maximum feed size: | 10 mm |

| Final fineness: | < 1 µm |

| Maximum capacity: | 450 ml |

| Grinding materials: | Agate, sintered corundum, silicon nitride, zirconium oxide, stainless steel, hardened steel, tungsten carbide |

| Dimensions (WxDxH): | Floor instrument 60x80x110 cm (24x32x44’’) |

| Weight: | 320 kg (705 lbs.) |

- Certified safety (CE mark) – optional CSA approval for Canada

- 2-year guarantee

In contrast to typical Planetary Mills, the innovative Vario Planetary Mill allows for configuration of the speeds for the grinding bowls, and the support disc, completely independent of each other. For the first time, it is possible to perform both mechanical activation, as well as mechanical alloying, with a single mill through modification of the gear ratio. By varying the transmission ratio, control the movements and trajectories of the grinding balls to emulate the desired grinding effect. Program the balls to strike the inner wall of the bowl vertically (high impact energy), approach each other tangentially (high friction) or just roll down the inner wall of the bowl (centrifugal mills).

- Program all the grinding parameters through PC software

- Real-time monitoring of the grinding process

- Fault free long service life

Related products

Crushers, Pulverizers, Grinders

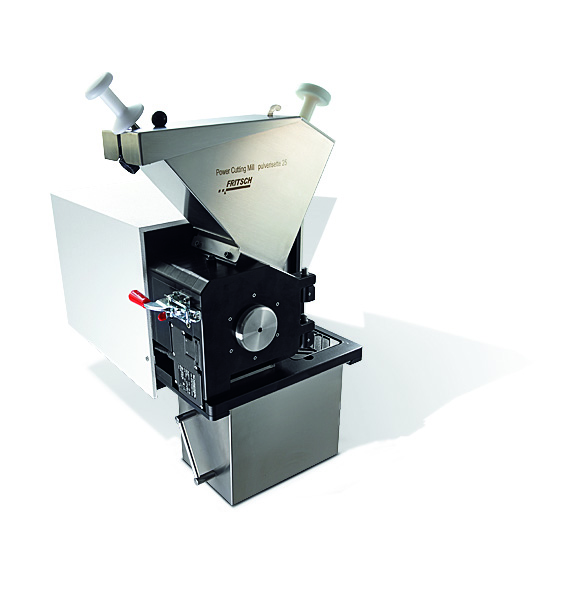

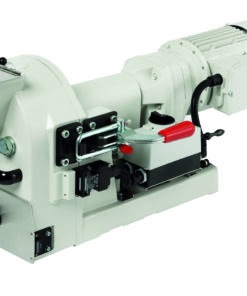

Power Cutting Mill Pulverisette 19 LARGE

$1The Pulverisette 19 Large is a powerful cutting mill for the coarse grinding of dry, soft to medium-hard or fibrous materials and plastics.

Crushers, Pulverizers, Grinders

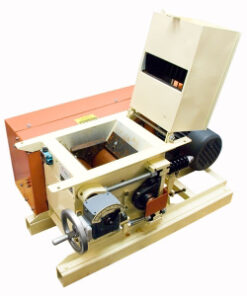

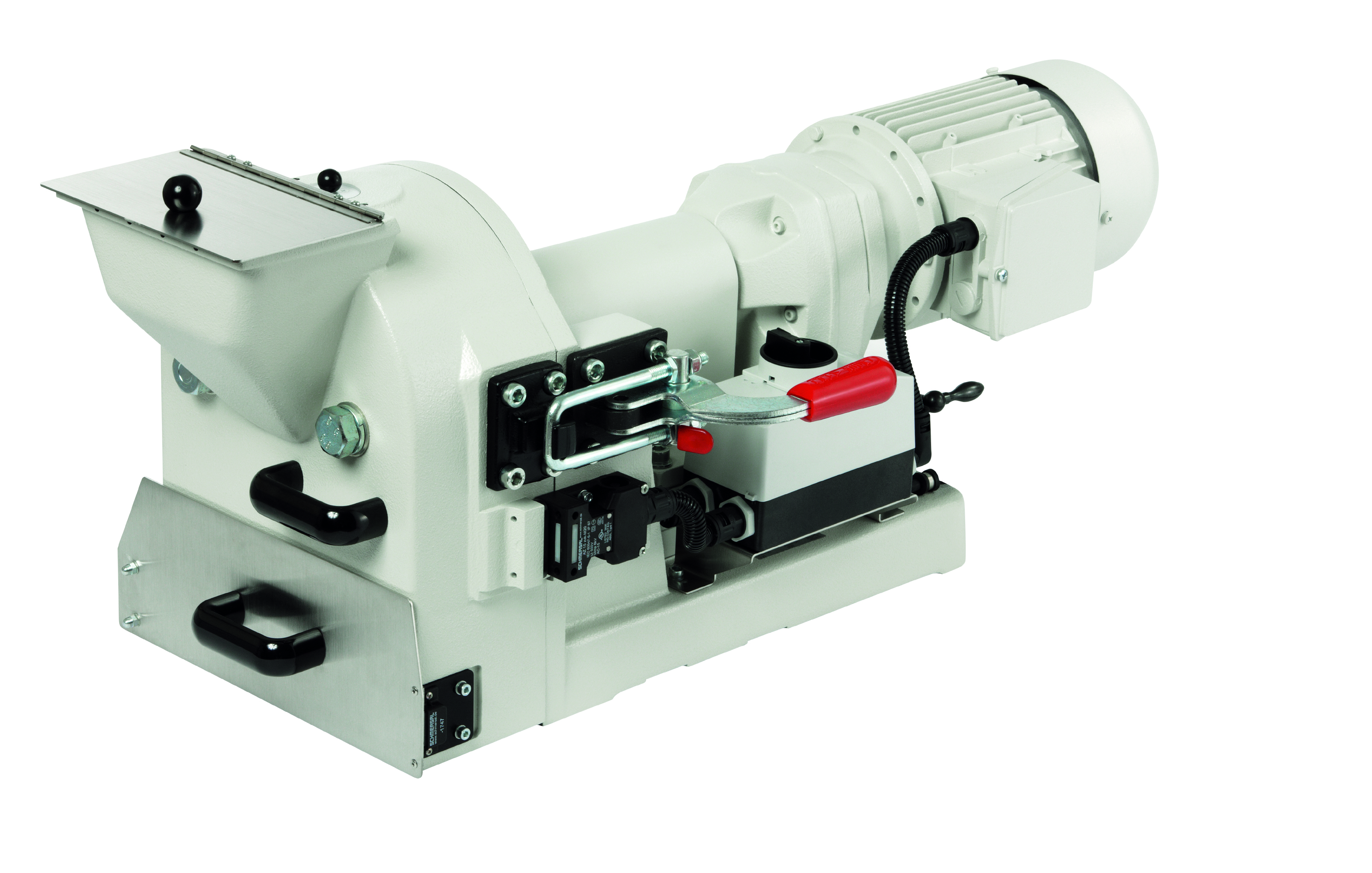

Marcy® Double Roll Crushers

$1The Marcy Double Roll Crusher meets your requirements for intermediate crushing of friable rock or rock-like materials

Crushers, Pulverizers, Grinders

Mortar Grinder Pulverisette 2

$0The Automatic Mortar Grinder Pulverisette 2 is ideal for universal grinding of medium-hard-brittle to soft-brittle materials (dry or in suspension) to analytical fineness, as well as for formulation and homogenisation of pastes and creams at laboratory scale.

Crushers, Pulverizers, Grinders

High-Tech Disc Pulverizer Pulverisette 13 Premium

$1The Laboratory Disc Pulverizer Pulverisette 13 Premium Line is designed for batch or continuous fine grinding of hard-brittle to medium-hard solids, down to 50µm.

Crushers, Pulverizers, Grinders

Crushers, Pulverizers, Grinders

Laboratory Mini Mill Pulverisette 23

$0The Mini Ball Mill Pulverisette 23 is used for fine grinding of small quantities of dry samples or solids in suspensions, as well as mixing and homogenisation of emulsions.

Crushers, Pulverizers, Grinders

Planetary Mono Mill Pulverisette 6

$0The Planetary Mono Mill Pulverisette 6 is recommended for extremely rapid, batch grinding of hard to soft material, dry or in suspension, down to colloidal fineness. It is also an ideal laboratory instrument for mixing and homogenising of emulsions.

Crushers, Pulverizers, Grinders

Laboratory Disc Pulverizer Pulverisette 13

$0The Laboratory Disc Pulverizer Pulverisette 13 is designed for batch or continuous fine grinding of hard-brittle to medium-hard solids.