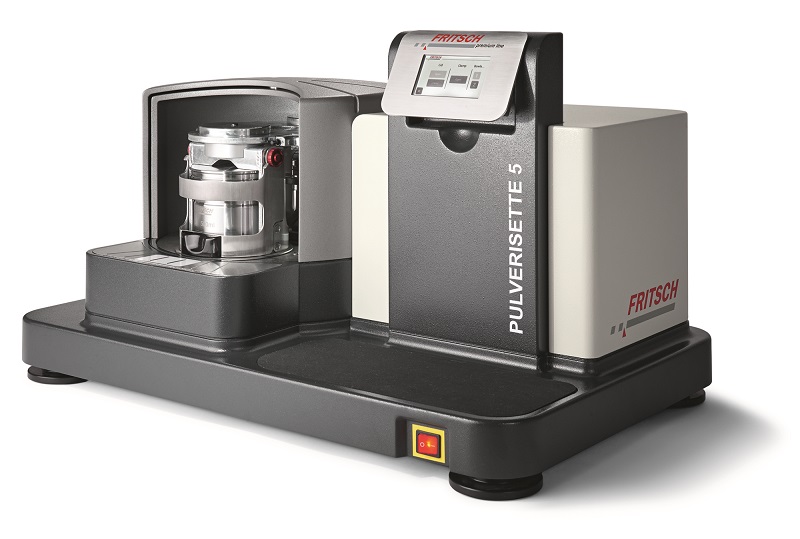

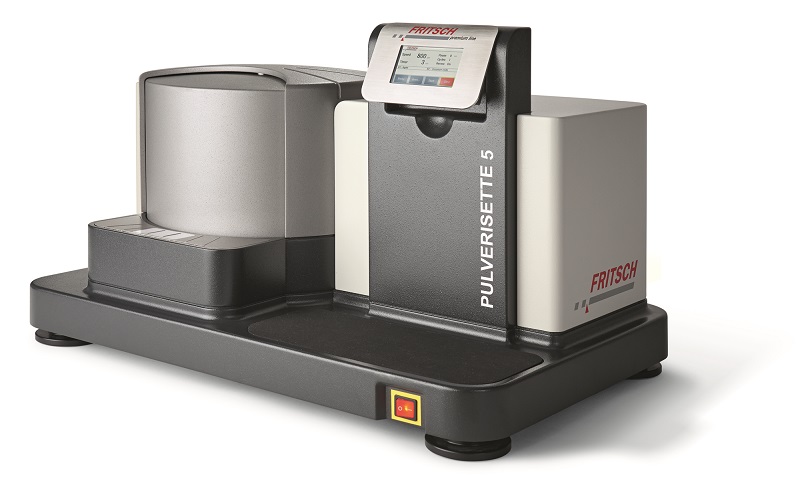

High Energy Planetary Ball Mill Pulverisette 5 Premium

The High Energy Planetary Ball Mill Pulverisette 5 PREMIUM with 2 working stations is the ideal mill for fast, wet or dry, grinding of larger sample quantities down to the nanometer range, with the highest safety standards.

Due to the extra strong 2.2 kW drive power, the Pulverisette 5 Premium can reach a centrifugal acceleration of up to 62 g, with 800 rpm speed (rotational speed of the bowl 1,600 rpm). This results in high-performance grindings, down into the nanometric range, with a unique capacity of up to 450 mL.

Intuitive user navigation

This High Energy Ball Mill features fast and easy operation; with a high-resolution touchscreen, logical menu structure in multiple languages, and practical, plain-text user navigation.

Grinding has never been safer

With the completely brand new ServoLOCK clamping of the grinding bowls and the automatic check of the fastening of the bowls inside the mill, the operator and the machine are optimally protected. In the event of impermissible operating states, the machine blocks the start of a grinding – and if an imbalance occurs, it automatically shuts off.

The revolutionary ServoLOCK is activated with a single hand motion by pressing down the clamp. The actual clamping is motor-driven by the mill. The advantage: each grinding always has the same conditions, with no screwing or manual fastening.

Reliable bowl detection

Via RFID chip the Pulverisette 5 Premium will not start until both bowls are correctly inserted. It also prevents setting too high speeds for the bowl material used. The results are constant and reliable; an incorrect operation is not possible.

Configure the Planetary Mill Pulverisette 5 Premium exactly to your specific application

The grinding bowls for the Planetary Mill Pulverisette 5 Premium are available in 150 ml, 250 ml and 500 ml sizes. This gives you flexibility for optimal adjustment to the specific sample volume.

To achieve the best grinding results, and for direct prevention of contamination of the samples due to undesired abrasion, grinding bowls and balls are available in different materials. For grinding in inert gas or for mechanical activation and alloying, premium line gassing lids with valves are available.

| Maximum feed size: | 10 mm |

| Final fineness: | < 100 nanometers |

| Maximum capacity: | 2 x 225 mL |

| Grinding materials: | Agate, zirconium oxide, hardened stainless steel, tungsten carbide |

| Dimensions (WxDxH): | Bench top instrument 82×52 x48 cm (32x21x19’’) |

| Weight: | 110 kg (242 lb.) |

Certified safety (CE mark) – optional CSA approval for Canada 2-year warranty

The comminution takes place primarily through the high-energy impact of grinding balls and partially through friction between the grinding balls and the grinding bowl wall. To achieve this, the grinding bowl containing the material to be ground and the grinding balls, rotates around its own axis on a main disk that is rotating in the opposite direction.

At a certain speed, the centrifugal force causes the ground sample material and grinding balls to bounce off the inner wall of the grinding bowl, cross the bowl diagonally at an extremely high speed, and impact the material to be ground on the opposite wall of the bowl. The grinding bowls reach twice the speed of the main disk during this process (up to 1,600 rpm).

- Extremely high acceleration of up to 62 g – 800 rpm (1600 rpm for the bowls)

- Ultra-fine grinding down to nanometric range

- Unique, high capacity of up to 450 mL

- German quality

Related products

Crushers, Pulverizers, Grinders

Planetary Ball Mill Pulverisette 5

$0The Planetary Ball Mill Pulverisette 5 allows fast and very fine grinding of hard to soft material, dry or in suspension, down to colloidal fineness. It can also be used for mixing and homogenising of emulsions and pastes.

Grinding capacity of up to 8 samples per operation.

Crushers, Pulverizers, Grinders

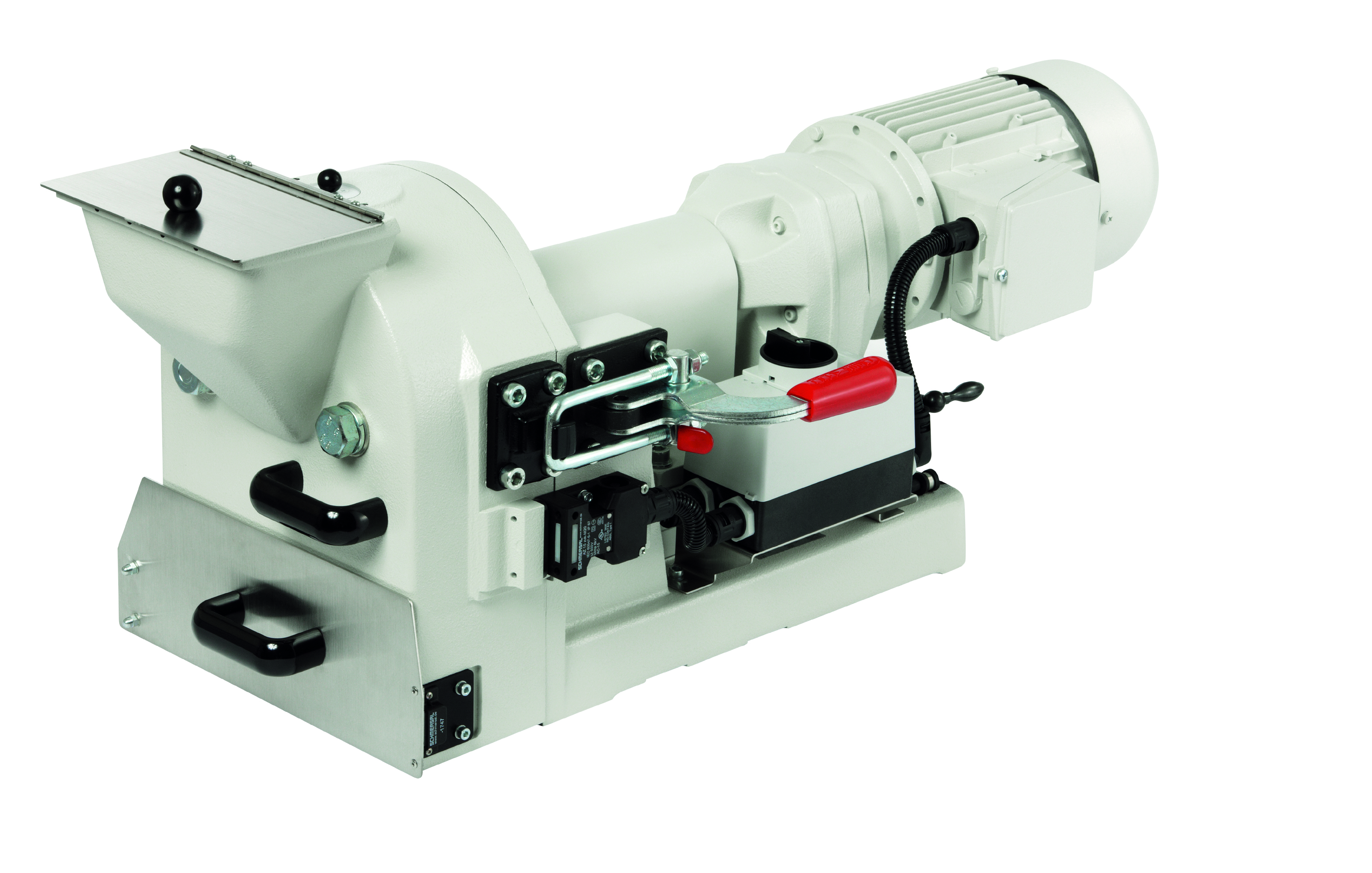

Laboratory Disc Pulverizer Pulverisette 13

$0The Laboratory Disc Pulverizer Pulverisette 13 is designed for batch or continuous fine grinding of hard-brittle to medium-hard solids.

Crushers, Pulverizers, Grinders

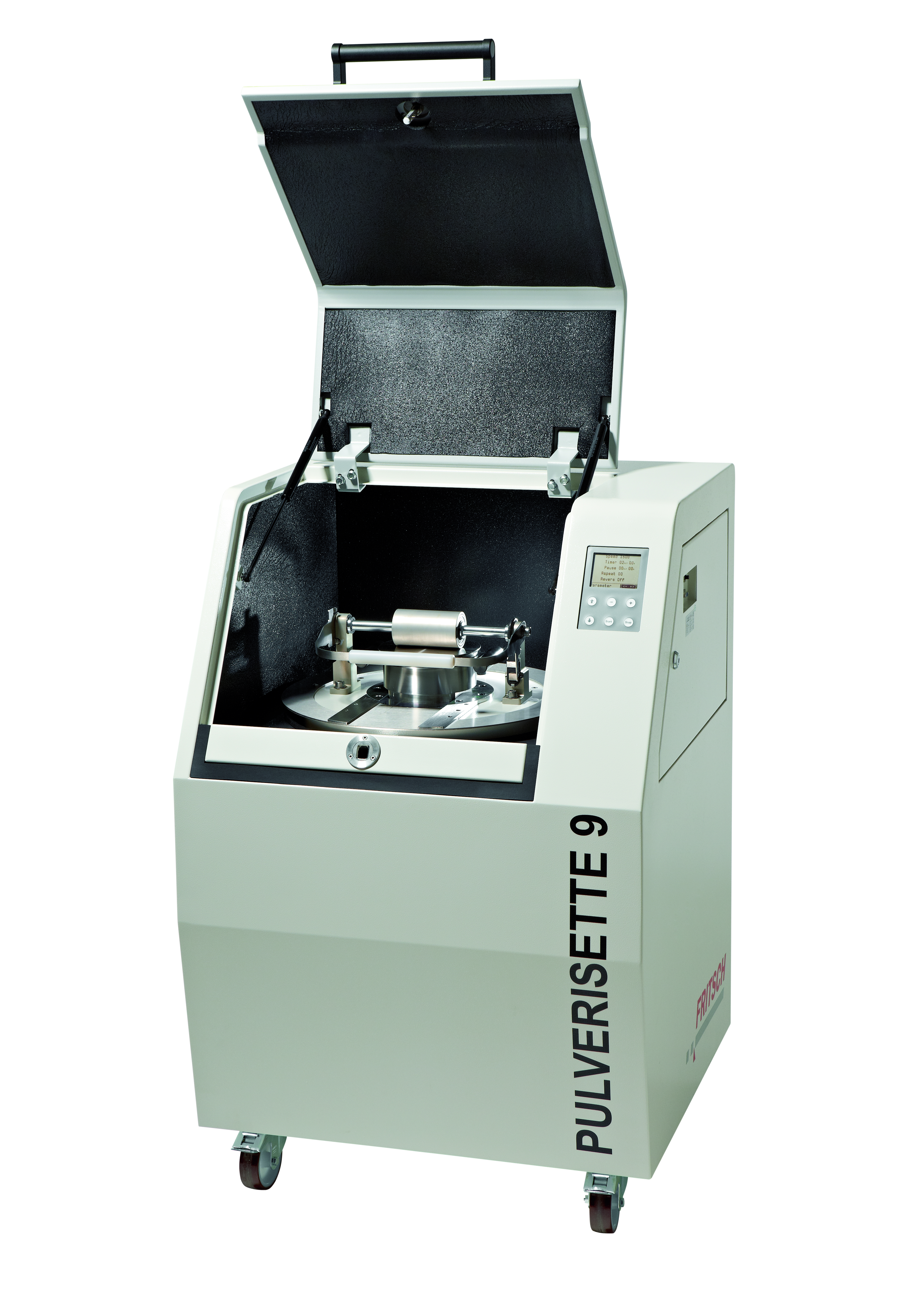

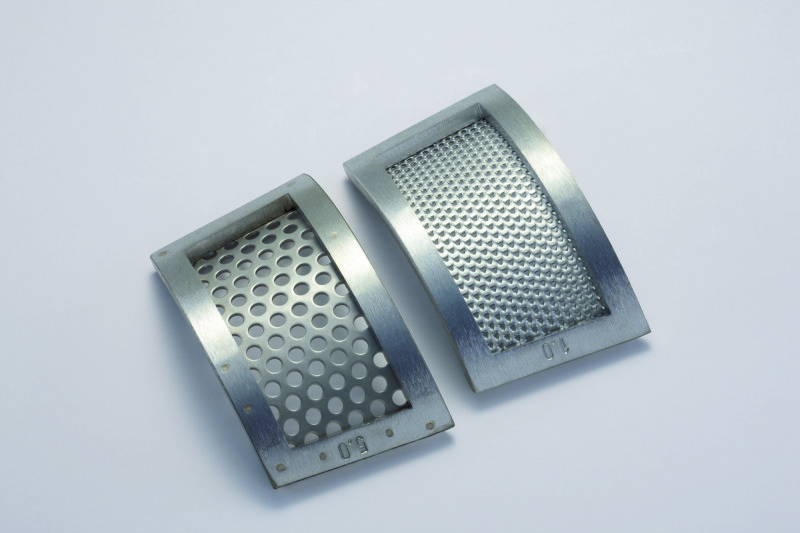

Laboratory Vibrating Cup Mill Pulverisette 9

$0The Ring & Puck Mill Pulverisette 9 is designed for extremely fast pulverizing (speed up to 1500 rpm) of hard, brittle and fibrous laboratory samples, dry or in suspension, down to analytical fineness.

Crushers, Pulverizers, Grinders

Laboratory Mini Mill Pulverisette 23

$0The Mini Ball Mill Pulverisette 23 is used for fine grinding of small quantities of dry samples or solids in suspensions, as well as mixing and homogenisation of emulsions.

Crushers, Pulverizers, Grinders

Variable Speed Rotor Mill Pulverisette 14 Premium

$1The Variable Speed Rotor Mill Pulverisette 14 Premium is a versatile, powerful mill for the fast grinding of medium-hard, brittle as well as fibrous materials and temperature sensitive samples.

Crushers, Pulverizers, Grinders

Crushers, Pulverizers, Grinders

Crushers, Pulverizers, Grinders

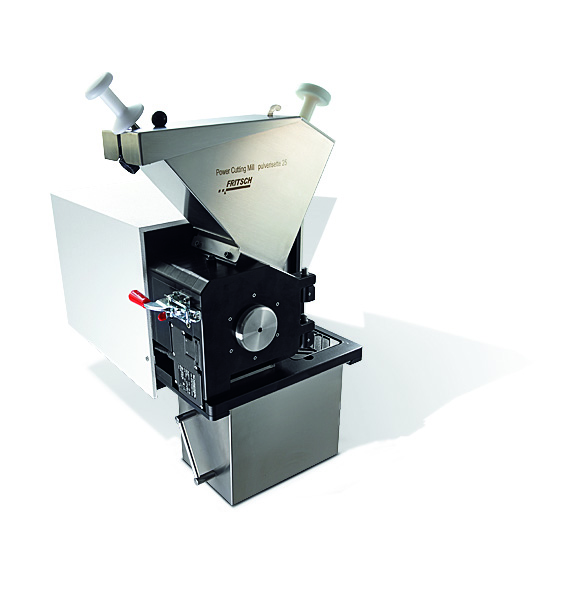

Power Cutting Mill Pulverisette 19 LARGE

$1The Pulverisette 19 Large is a powerful cutting mill for the coarse grinding of dry, soft to medium-hard or fibrous materials and plastics.