Laboratory Vibratory Micro Mill Pulverisette 0

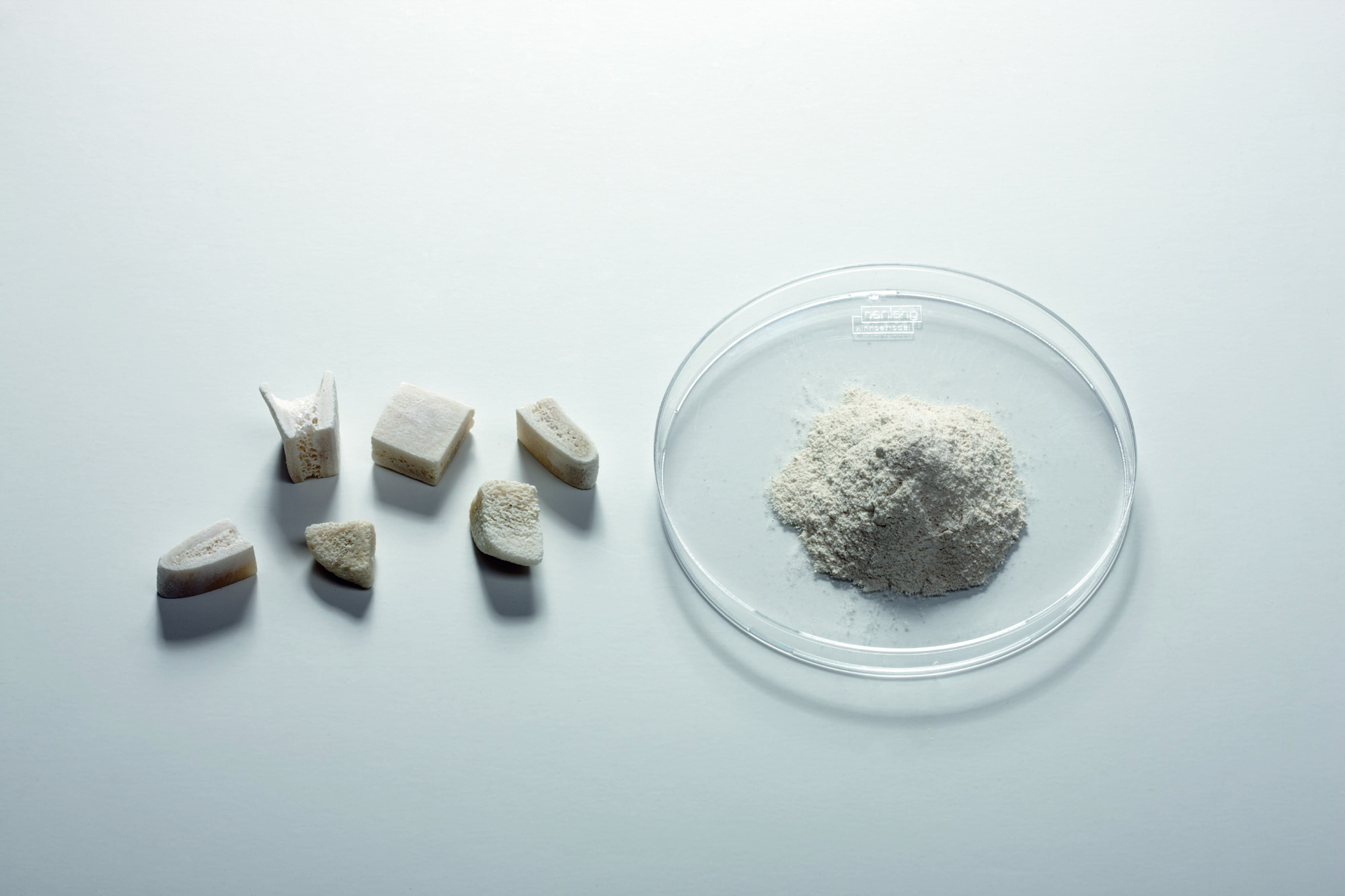

The Micro Mill Pulverisette 0 is designed for fine grinding of dry laboratory samples or solids in suspension, and for homogenisation of emulsions or pastes.

The Vibratory Micro Mill Pulverisette 0 grinds your sample through impact and friction by which the mortar vibrates electromagnetically and the grinding material transfers the vibrations to the grinding ball.

At the beginning of the grinding, the crushing of the coarse particles is achieved by the impact effect of the grinding ball. Next, the fine particles are ground through friction by the tumbling motion of the grinding ball as the vibrations subside.

The impact energy of the grinding ball is freely adjustable thus, allowing it to be precisely adapted to the sample.

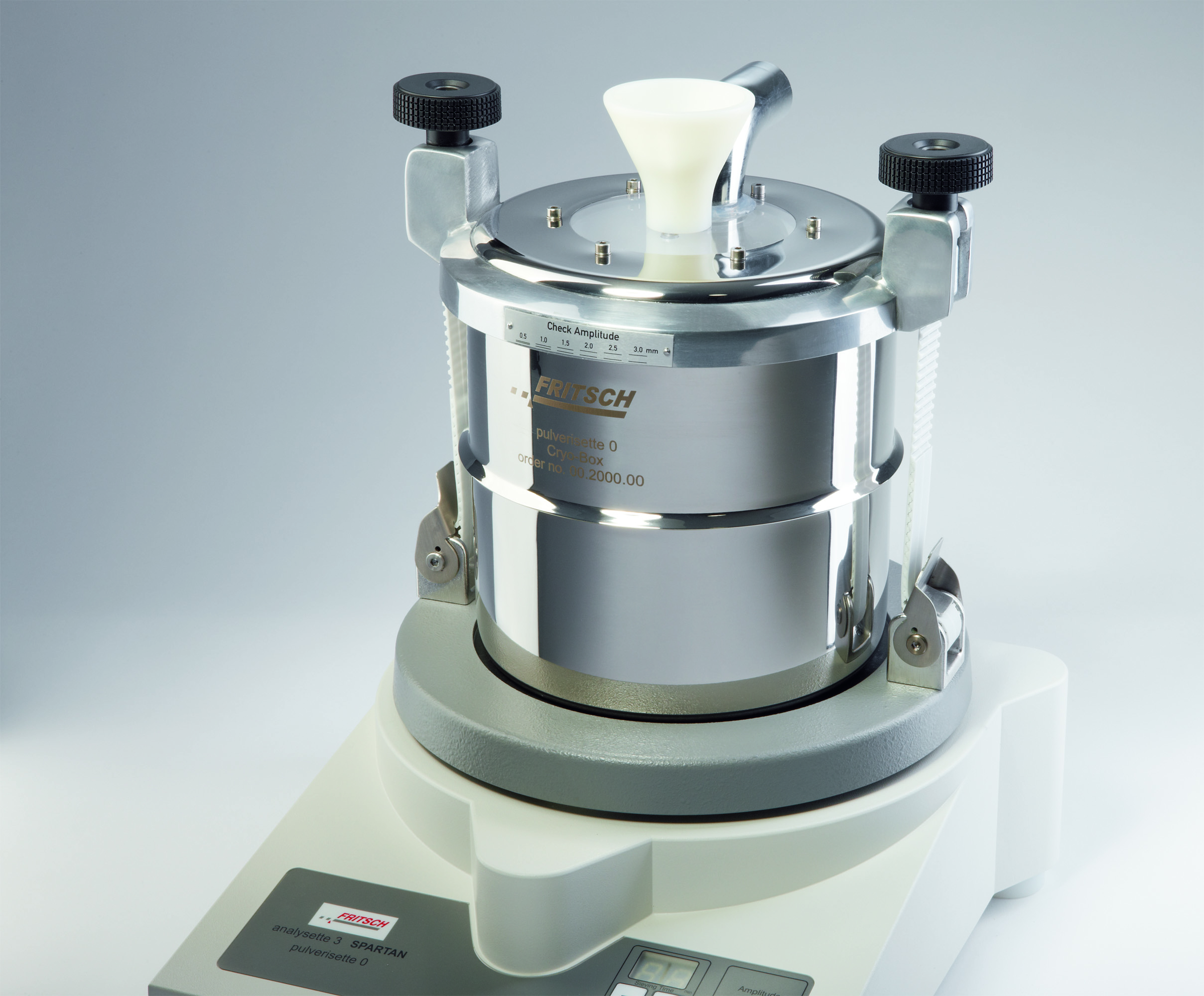

For fast embrittlement of soft, slightly oily, fatty or moist materials for cryogenic grinding, we offer the cryo-box: simply insert the filled grinding set into the cryo-box and fill it with liquid nitrogen. With this method even extremely difficult-to-grind samples can be ground down to analytical fineness. And the thick insulation ensures a particularly efficient use of coolant.

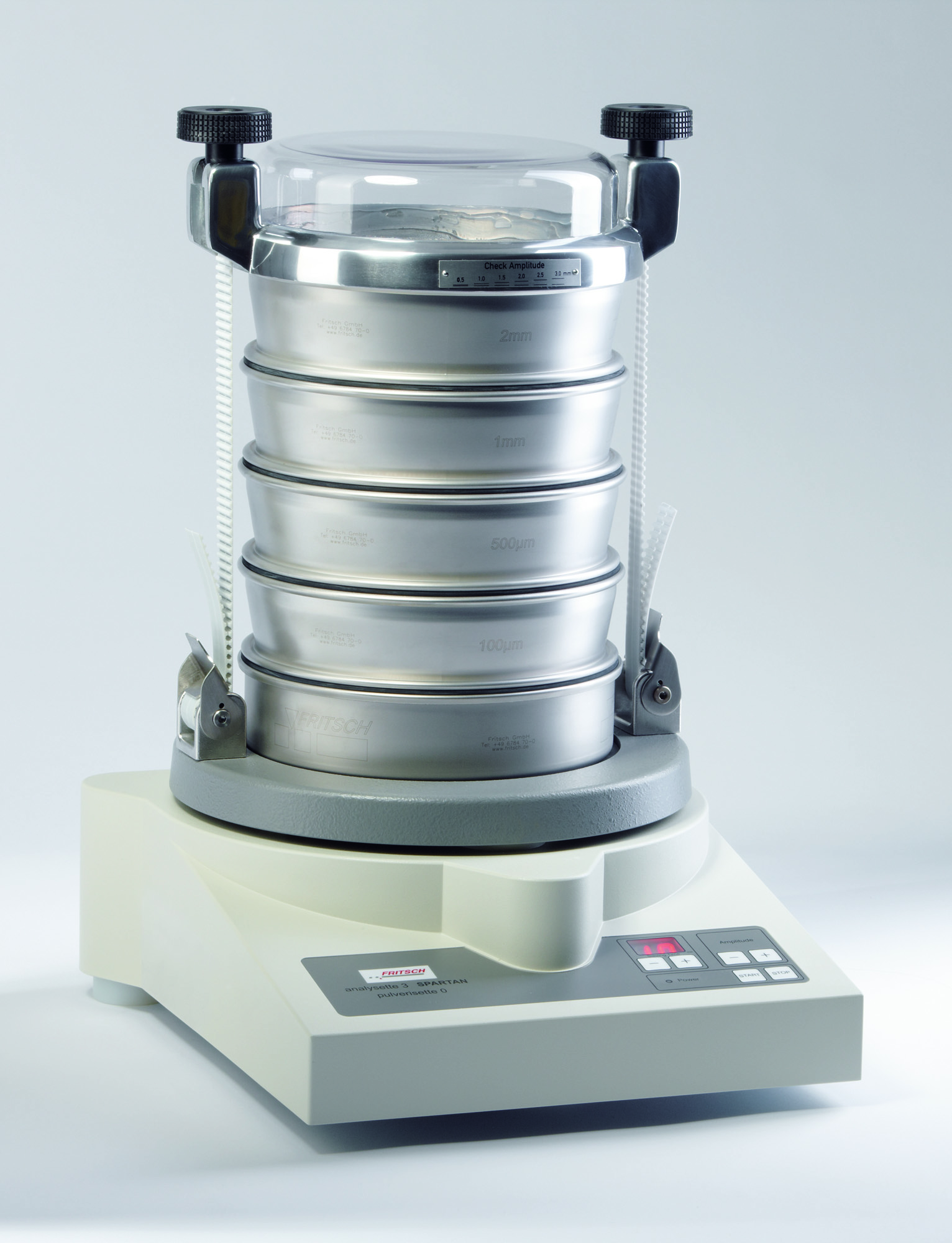

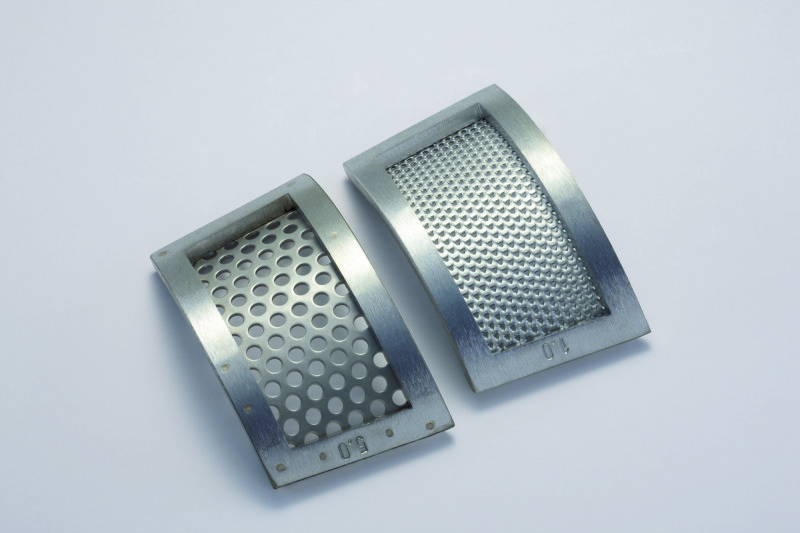

This Mill can be converted to a Vibratory Sieve Shaker for quantitative particle size analysis of solids (measuring range 32 μm – 63 μm) and suspensions (measuring range 20 μm – 10 mm) by simply inserting corresponding sieves.

Application: small laboratory samples.

| Maximum feed size: | 5 mm |

| Final fineness: | down to 10 µm (depending on material) |

| Maximum capacity: | 10 ml |

| Grinding materials: | agate, sintered corundum, zirconium oxide, stainless steel, tempered steel, tungsten carbide |

| Dimensions (WxDxH): | bench top instrument 37x40x20 cm (15x16x8’’) |

| Weight: | 21 kg (46 lb.) |

- Certified safety (CE mark) – optional CSA approval for Canada

- 2-year warranty

The Vibratory Micro Mill Pulverisette 0 achieves size reduction through the combination of impact and friction. An electromagnetically powered mortar generates vibrations. These vibrations are transferred to the grinding ball via the grinding material. The impact energy of the grinding ball can be controlled to suit the application.

- Effective grinding in a narrow particle size range, dry or in suspension

- Cryogenic grinding with liquid Nitrogen and cryo-box option

- Modular system for simple conversion to a sieve shaker

- German quality

Related products

Crushers, Pulverizers, Grinders

High-Tech Disc Pulverizer Pulverisette 13 Premium

$1The Laboratory Disc Pulverizer Pulverisette 13 Premium Line is designed for batch or continuous fine grinding of hard-brittle to medium-hard solids, down to 50µm.

Crushers, Pulverizers, Grinders

Planetary Ball Mill Pulverisette 5

$0The Planetary Ball Mill Pulverisette 5 allows fast and very fine grinding of hard to soft material, dry or in suspension, down to colloidal fineness. It can also be used for mixing and homogenising of emulsions and pastes.

Grinding capacity of up to 8 samples per operation.

Crushers, Pulverizers, Grinders

Crushers, Pulverizers, Grinders

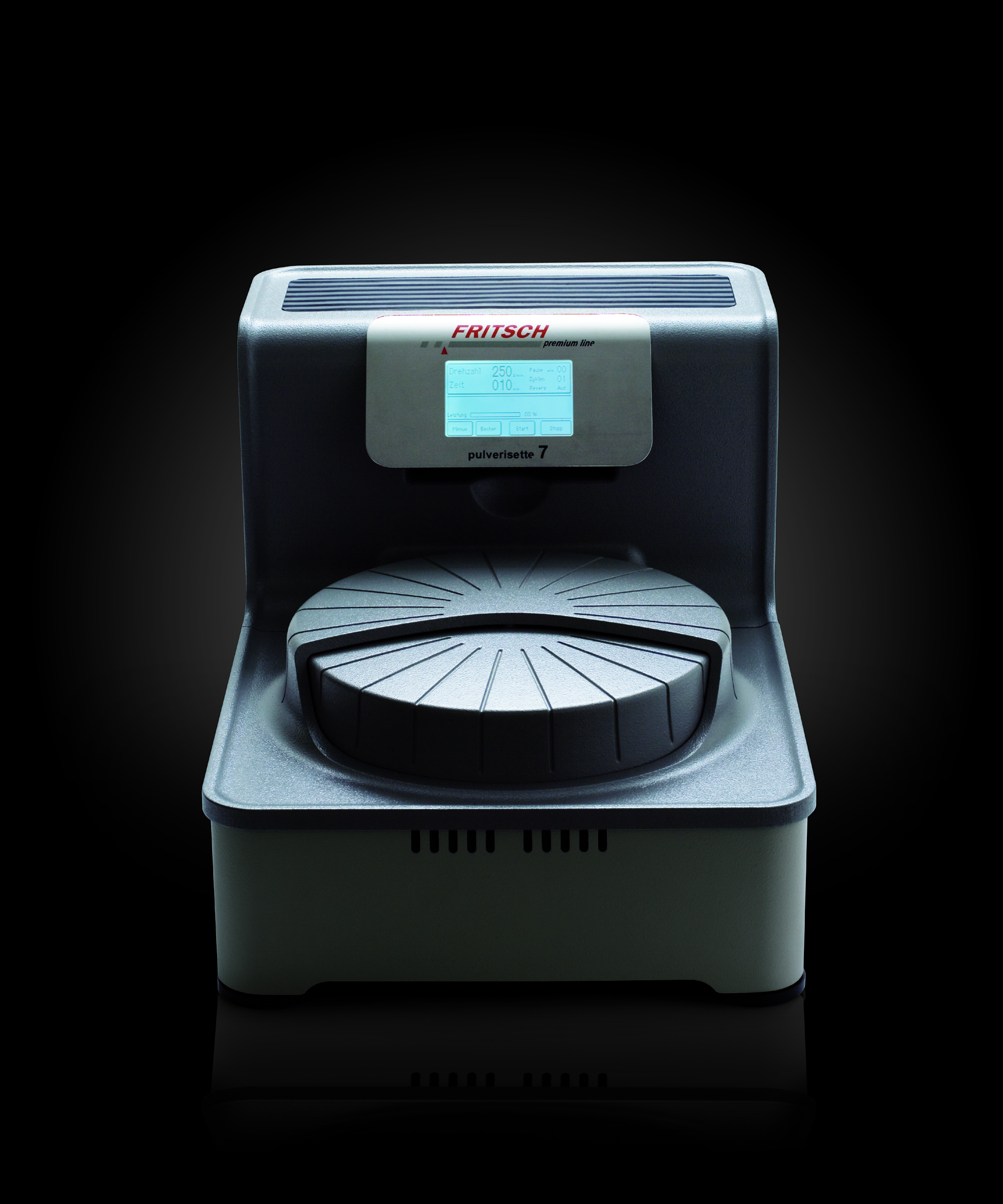

Planetary Micro Mill Pulverisette 7

$0The Planetary Micro Mill Pulverisette 7 is designed for uniform, and extremely fine size reduction of very small samples of hard to soft material, dry or in suspension, down to colloidal fineness. Also designed for mixing and homogenising of emulsions or pastes.

Crushers, Pulverizers, Grinders

Cutting Mill Pulverisette 19 for Cannabis Processing

$1The Pulverisette 19 Universal Cutting Mill System has been optimized for Cannabis Processing.

Crushers, Pulverizers, Grinders

Nano Range Planetary Mill Pulverisette 7 Premium

$0Thanks to the high rotational speed of up to 1100 rpm for the main disc, this high-tech Planetary Mill, Pulverisette 7 Premium, easily grinds down to the nanometer range.

Crushers, Pulverizers, Grinders

Laboratory Jaw Crusher Pulverisette 1

$0This Laboratory Jaw Crusher is designed for fast and effective pre-crushing of very hard, hard, medium-hard, and brittle materials, even ferrous alloys.

Crushers, Pulverizers, Grinders

Planetary Mill Pulverisette 4 for mechanical alloying and mechanical activation

Planetary Mill Pulverisette 4 for mechanical alloying and mechanical activation

$1The Vario Planetary Mill Pulverisette 4 is ideal for mechanical activation and alloying. It offers the freedom to program all grinding parameters through PC software to achieve the desired effect on the sample.